As our country's construction is getting faster and faster, some large and small engineering projects can be seen everywhere. This also means that the market demand for building formworks is also increasing. However, with the continuous development of construction technology, engineering requirements for materials are also increasing. The previous building shuttering can only meet the basic construction needs, but there are many troubles in operation. Therefore, new building formwork have become the latest choice for many engineering projects and have a breakthrough significance.

So, what should be paid attention to in the installation of building formwork?

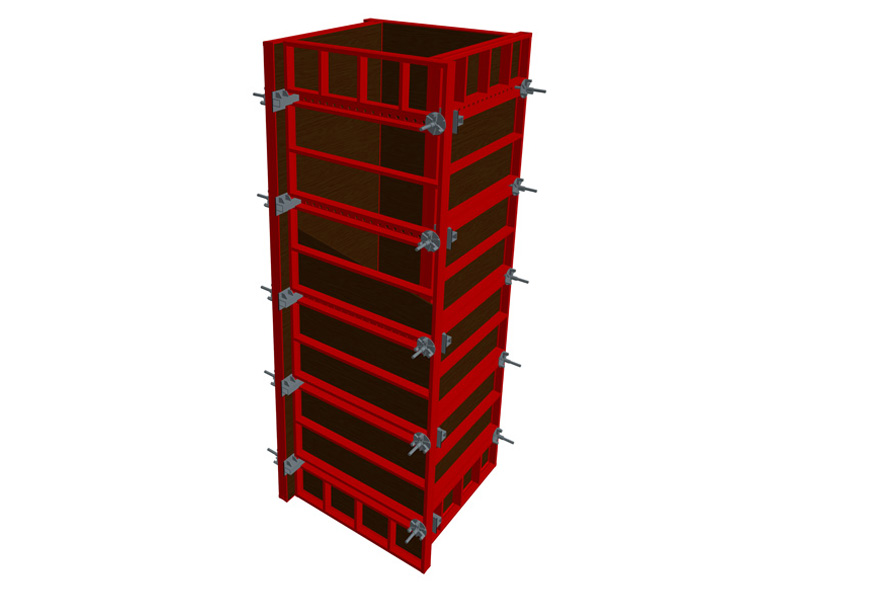

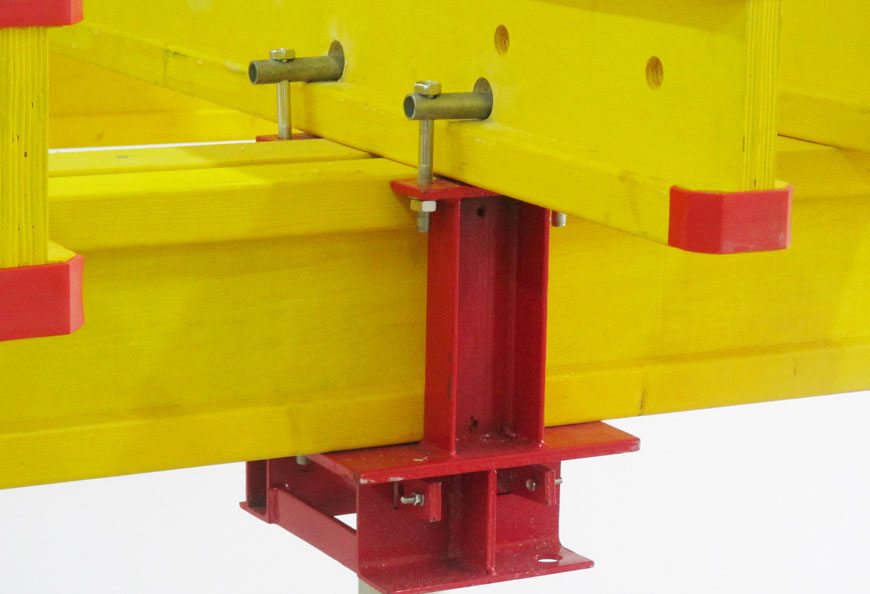

1. For multi-layer cast-in-place structures, the upper building formwork and brackets must be supported on the lower floor slab. At this time, three points should be paid attention to. First, the lower floor should have sufficient bearing capacity, and brackets should be added when necessary; second, the columns of the upper and lower racks should be basically aligned; third, the slabs should be laid under the columns of the brackets. In construction, the requirements for laying pads are applicable to floors and the building formwork columns installed on the ground.

2. The joints of the building formwork should not leak: the leaking of the building formwork will cause the honeycomb section of the concrete appearance and directly affect the quality of the concrete. Therefore, no matter what material is used to make the building shuttering, its joints should be tight and not leak. When wooden building formwork is used, the joints during installation of the wooden building formwork should not be too tight because the wood will expand and contract due to water absorption. After installation, it should be watered and moistened to close the template joints. Water until it is wet, and there should be no accumulation of water in the building formwork.

3. The interior of the building shuttering should be cleaned up. The debris left in the building formwork will cause defects such as slag inclusion in the concrete. In order to clear the building shuttering, a cleaning port should be reserved.

4. The building shuttering should be painted with a release agent. Choose oily release agents that do not affect the structure and hinder the construction of decoration projects. At the same time, it should be noted that the isolating agent will contaminate the contact between the steel bar and the concrete, which may cause obvious adverse effects on the mechanical performance of the concrete structure. Therefore, it is necessary to avoid contaminating the steel bars when painting.

5. When supporting the building shuttering, the embedded parts and reserved holes should be fixed simultaneously, without leaving the embedded parts, reserved holes and reserved holes on the building shuttering, and the size meets the requirements, and the installation is firm. The deviation meets the needs of the acceptance specification.

TECON provides concrete formwork (blinds) and scaffolding for global projects and has many years of experience dealing with contractors, builders and architects. We are one of the leading concrete formwork and scaffolding engineering formwork manufacturers and suppliers in China. If necessary, please consult.