XT Phayathai is a condominum project which has been developed by Sansiri. The project is located at 507/1 Thanon Si Ayutthaya, Khwaeng Thanon Phaya Thai, Khet Ratchathewi, Krung Thep Maha Nakhon 10400. They also have developed Condo Pinklao, the XXXIX, and D condo.

Land area : Approximately 3 Rai

Project type: 1 Residential building (Tower A 41 stories and Tower B 37 stories)

Total unit: 1435

Completion: the year 2023

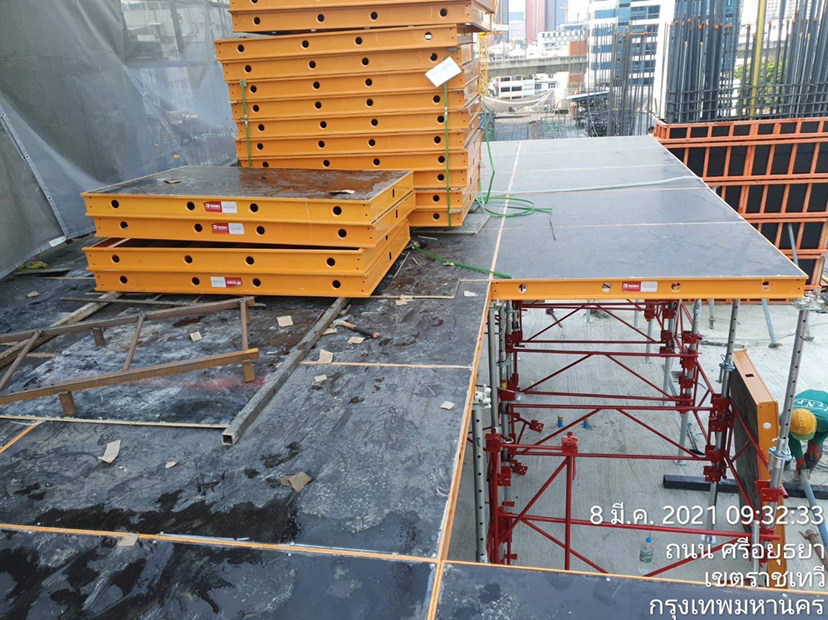

Formwork system: Slab-3000 SQM TOPEC, Wall-2000 SQM TP60

Excessive noise is not allowed because this project is located in the center of the city. Thus, we chose plastic formwork for the vertical structure. Also, the wall thickness is only 70 mm which is considered as a complicated structure. It is difficult to control the verticality. However, we have made some special reinforcement to solve this problem. We have sent samples to Thailand for wall pouring test to make sure that the project goes successfully.

As the summary of the project above, it is a high-rise building. TOPEC which consists of aluminum panels with 10 mm birch plywood is the best choice for the slab structure under demanding construction time. By using this system, the maximum slab thickness will be 700 mm for one time pouring with the panel area of 1.8*1.8 m. We could say that it is able to provide high output for our clients.

When our clients try to bring in a new product to their job site, they have a main consideration. They will focus more on the use of labour force. As you using this system, it is able to help contractors or companies to save labour greatly. At the same time, two workers are able to assemble them efficiently for 8 hour per day. The area can reach up to 180 square meter. This is the reason that our partner in Thailand chose this system for their project.