As Africa’s population continues to grow, the pressures on the housing market are intensifying, making it increasingly difficult for many people to acquire decent housing. This issue is particularly concerning in urban areas, where rapid and poorly planned construction is leading to unsanitary slums, further exacerbating the shortage of adequate housing for families. Thus, the government has placed affordable housing in their 2021-2025 strategic plan, particularly social housing.

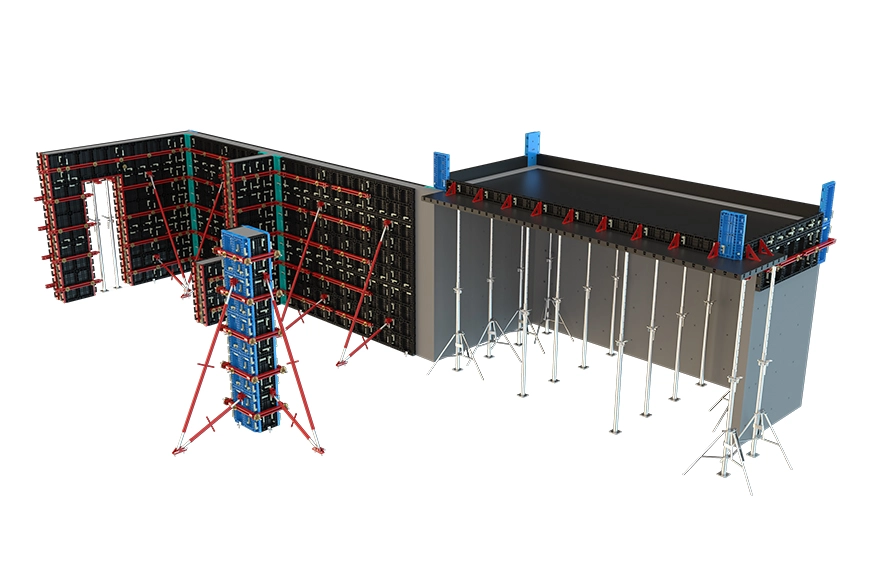

When constructing affordable housing, formwork is typically used for concrete pouring. Additionally, it is essential to set the working access to help with pouring job and ensure the working safety. Our Ringlock Scaffolding system fully meets these requirements. One of client who is the specialist of building affordable housing has purchased our system and used in Nigeria. The following is the brief information of the project.

Project type: Affordable housing

Project location: Nigeria

System used: TECON Ringlock Scaffolding

Product usage: Facade platform and work access

Quantity of products: 100 tons

The Ringlock scaffolding system offers multiple solutions for your project with its flexibility and high versatility. For example, connections can be made with just a hammer, and it can be set up at various angles. It is capable of constructing complex scaffolding towers for shoring support. At your project site, it can also be used as a facade platform to ensure worker safety. As shown in our project site pictures, our client used it as a working access with ledgers. This facilitates workers in performing peripheral tasks such as painting walls.

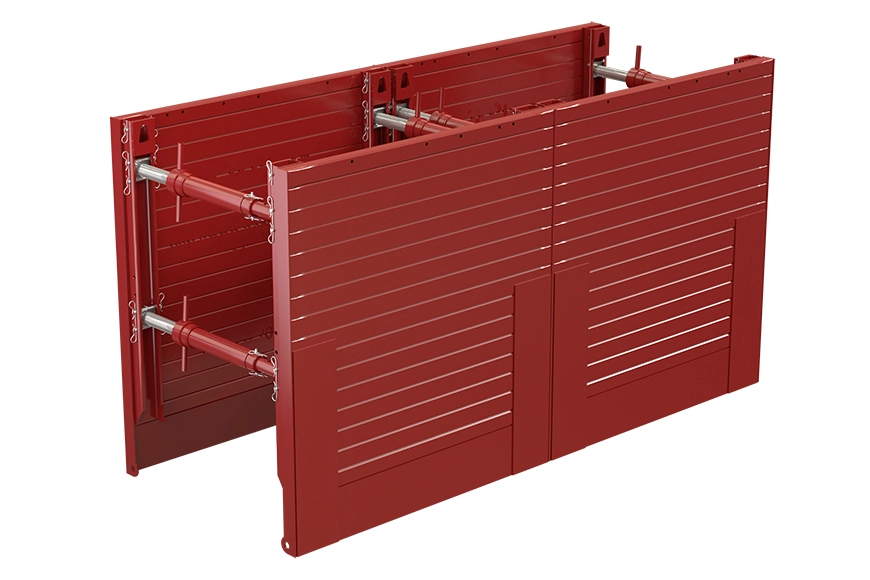

Despite its multifunctional usage, the Ringlock scaffolding system can also help reduce your overall and labor costs. Firstly, its durability is a key factor. The surface treatment, usually galvanized or painted coatings, protects against weathering and corrosion. With proper maintenance, Ringlock scaffolding can have a service life of 10 to 15 years. Secondly, its efficiency allows workers to quickly set up and dismantle the system due to its modular design with few components. This enables workers to spend more time focusing on the task at hand.

In summary, as demonstrated, Ringlock scaffolding offers numerous advantages over other types for commercial and industrial projects. Its modular design allows for quick assembly and dismantling, maximizing worksite efficiency and safety. The interlocking components provide a sturdy, wobble-free platform for workers at various heights. Additionally, Ringlock scaffolding reduces material waste and costs, with its galvanized steel parts being highly durable and weather-resistant. For accessibility, productivity, and a lower total cost of ownership, Ringlock scaffolding is the clear choice for large-scale projects.