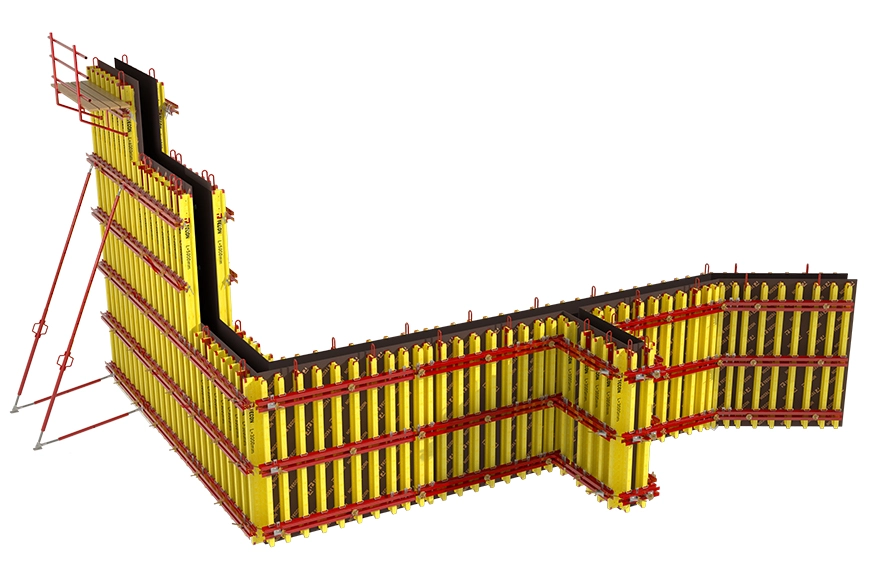

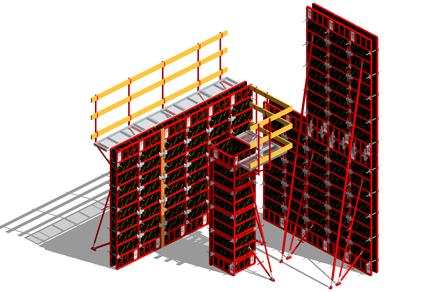

The metal formwork system is a formwork system used in construction, usually made of metal materials (such as steel or aluminum), used for casting concrete structures. The formwork system is a supporting structure in construction to maintain the shape of the concrete before it sets. The metal formwork system is more durable, stronger, and can be reused multiple times compared to traditional wooden formwork systems, thus improving construction efficiency and reducing waste. The metal formwork system, especially the aluminum alloy formwork, has the following significant features and advantages:

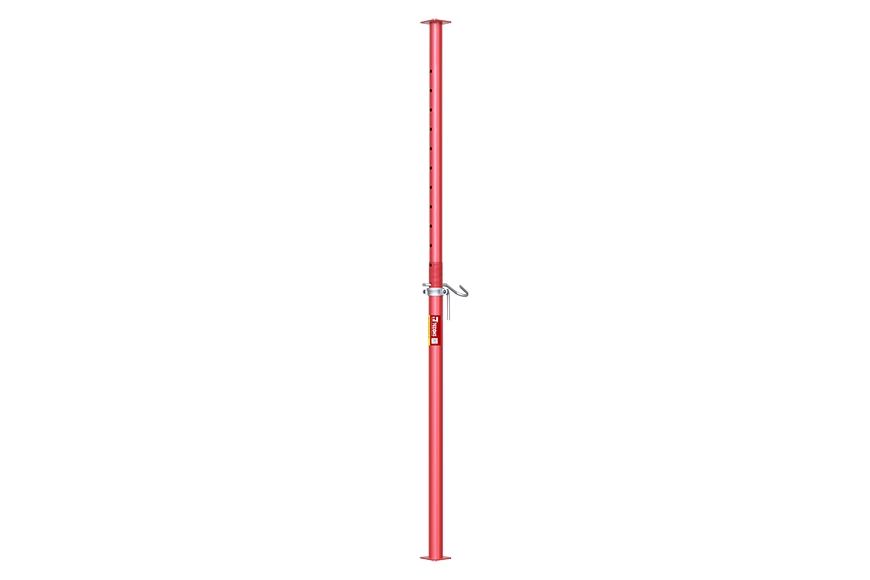

The metal formwork system employs quick-release technology, achieving one layer every 4-5 days, significantly shortening the construction period. It is standardized in the factory, and the installation and dismantling time is short, speeding up the construction progress.

The metal formwork system has a long service life and high turnover times, with over 300 uses domestically and even records of over 3000 uses abroad. Because the concrete surface is smooth, it eliminates the need for post-processing such as plastering and cutting, thus saving a large amount of material and labor costs.

The metal formwork system is made entirely of non-combustible metal materials, completely eliminating fire accidents.

The metal formwork system components can all be reused. After dismantling the formwork, there is no garbage on site, allowing workers to operate in a relatively spacious, clean, and safe working space.

Before construction, professionals use computer-aided design to standardize, modularize, and systematize all the required formworks, thus achieving integrated casting of wall formworks, top formworks, and support systems.

These features make the metal formwork system widely applicable in construction, especially in modern construction projects that pursue high efficiency, high quality, and environmental protection.