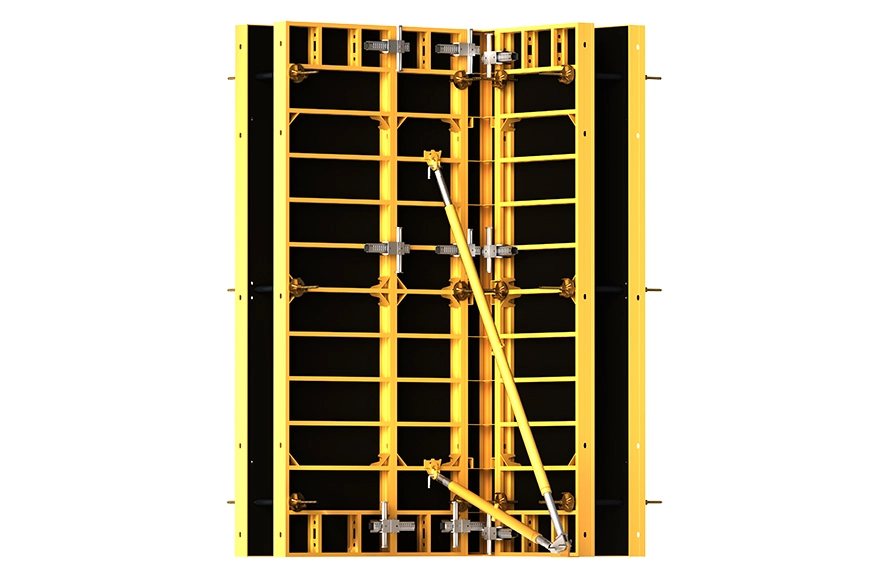

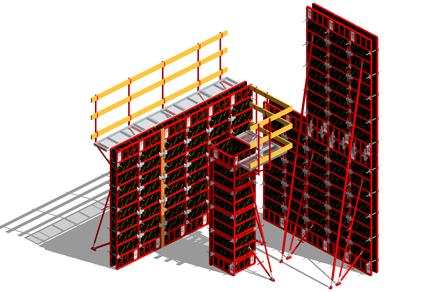

The wooden formwork consists of panels and a support system. The panels are the parts that shape the concrete; the support system is the structural part that stabilizes the positions of the panels and bears the upper load.

The quality of the wooden formwork is crucial to the quality of concrete engineering, with accurate dimensions, firm assembly, tight seams, and easy installation and removal being key factors. An appropriate form of the formwork should be chosen based on the structure's form and characteristics to achieve good technical and economic results. The formwork and support systems for large and special projects need to be calculated and their rigidity, strength, stability, and ability to withstand lateral pressure must be verified.

Wooden formwork composition: panels and support system.

Foundation formwork for wooden formwork: uses pine boards, poplar boards, eucalyptus boards, etc.

Function of wooden formwork: ensures the accuracy of the positions of each part of the components.

The surface of wooden formwork is smooth and flat, the quality is hard and durable, with good color and high quality.

Large board width and flat surface. This feature significantly reduces the workload during construction, requiring fewer personnel for formwork installation, concrete pouring, and formwork removal, saving a lot of labor costs and reducing the expenses for decorating and grinding the exposed surfaces and seams of the concrete.

High bearing capacity, able to effectively bear the pressure during concrete pouring as well as the lateral pressure of the concrete. Additionally, the surface is treated with a film, making it smooth, wear-resistant, and suitable for multiple uses.

Lightweight material, constructed from 18mm thick multi-layer plywood, the unit area weight is only 50 kilograms. One or two workers can easily move the formwork without mechanical assistance, saving costs. Moreover, it is much easier to stack, use, and manage compared to steel formworks.

Easy to bend and form. Wooden cylindrical formworks, special shape formworks, etc., are often produced through high-temperature hot pressing, making it easy to adapt to the installation needs of construction projects and create various curved surface formworks.

Easy to saw. The core material is wood, which can be cut with an electric saw. Depending on the length or height requirements of different construction projects, the wooden formwork can be cut to fit the building's height, facilitating construction.

Good thermal insulation performance. Wood has a low effect on heat transmission, effectively preventing rapid temperature changes in the concrete, making it especially suitable for winter construction. It helps in maintaining the insulation of concrete during winter construction.