Formworks for column are temporary structures used in construction to support and shape concrete columns. Their primary function is to ensure that the concrete maintains the correct shape and dimensions during the pouring process and to provide protection and curing during the hardening process. Below is a detailed introduction to formworks for column:

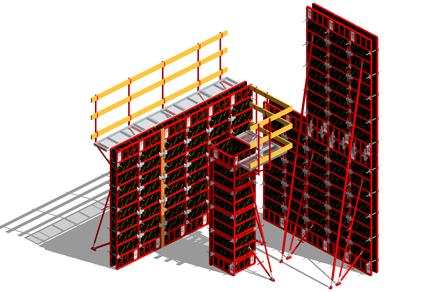

Formworks for column typically consist of the formwork itself, supporting components (such as columns, beams, and bracing), and fastening components (such as bolts and nails).

Wooden Formworks for Column: Made from wood, suitable for the construction of various types of columns, especially in small and medium-sized buildings.

Steel Formworks for Column: Made from steel plates, offering high strength and stability. These are widely used in industrial and large-scale building column construction.

Plastic Formworks for Column: Made from plastic materials, lightweight, easy to handle and install. They are suitable for small and medium-sized building columns.

Combination Formworks for Column: These combine different materials such as wood, steel plates, and plastic, meeting the needs of different projects.

Installation: First, the column axis and edge lines are marked on the base or floor. Then, the formwork and supporting structure are installed according to design specifications.

Concrete Pouring: After the formwork is installed, concrete is poured to ensure uniform distribution and maintain the required shape and dimensions.

Removal: Once the concrete reaches a certain strength, the formwork and its supporting structure are removed in a specific order.

Lightweight: Compared to steel formwork, wooden or plastic formwork is lighter and easier to transport and install.

Easy to Process: It can be cut and fixed using standard carpentry tools.

Cost-Effective: Wooden formwork is generally more affordable, making it suitable for large-scale construction projects.

Reusability: Wooden formwork can be reused multiple times, saving resources.

By selecting and using formworks for column correctly, construction efficiency can be effectively improved, ensuring high construction quality while reducing costs.