Steel formwork plays a crucial role in the modern construction industry. Its correct use can not only improve construction efficiency but also ensure the quality and safety of the project. This article will provide a detailed guide on the correct use of steel formwork, including aspects such as selection, installation, usage, and maintenance, to help readers better master the skills of using steel formwork.

When purchasing steel formwork, pay attention to the following points:

Specifications and dimensions: Choose the appropriate specifications and dimensions based on project needs to ensure the formwork can meet construction requirements.

Material quality: Select formworks made from high-quality steel, which have high strength and durability.

Surface treatment: Check whether the surface of the formwork is flat and smooth, without rust, oil stains, or other impurities.

When installing steel formwork, pay attention to the following points:

Foundation treatment: Ensure the construction foundation is flat, solid, free from debris and water accumulation.

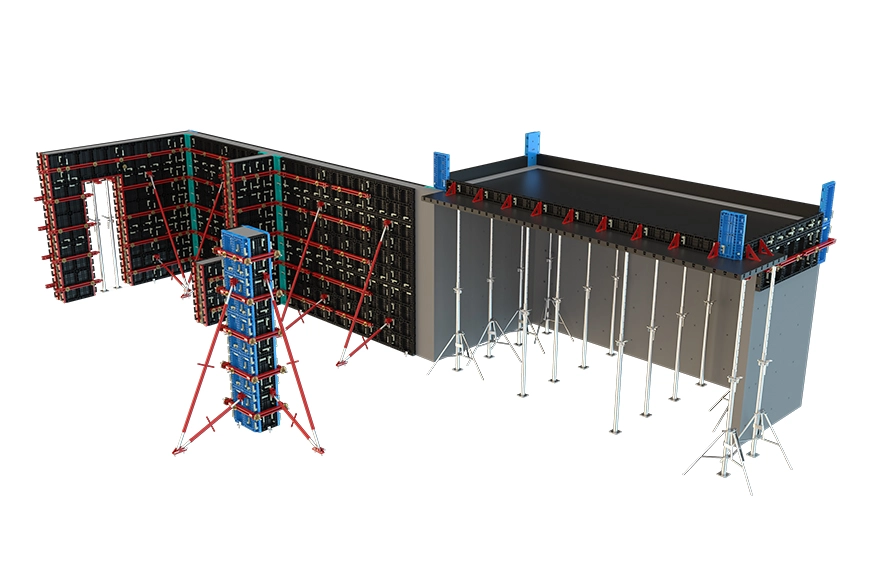

Positioning and calibration: Accurately position the formwork according to construction drawings and design requirements, and perform calibration.

Firm fixation: Use special clamps or support frames to firmly fix the formwork, preventing displacement or deformation during construction.

When using steel formwork, pay attention to the following points:

Construction sequence: Set up and dismantle the formwork step by step according to the construction drawings and plans.

Operation norms: Construction personnel should be familiar with the operation norms and follow safety procedures to ensure safety during the construction process.

Quality inspection: Regularly inspect the formwork during the construction process to ensure its position, dimensions, and stability meet requirements.

When maintaining steel formwork, pay attention to the following points:

Cleaning and upkeep: Regularly clean the formwork, removing concrete residues, oil stains, and other impurities on the surface to keep it clean and tidy.

Anti-corrosion treatment: Perform anti-corrosion treatment, such as applying anti-rust paint or plastic spraying, to extend its service life.

Storage management: Store the formwork in a dry, ventilated place to avoid moisture, rust, and damage. Also, classify and store according to specifications and dimensions for convenient future use.

Besides the above points, consider the following:

Adherence to safety regulations: Strictly follow safety regulations when using steel formwork, such as wearing safety helmets, gloves, and other protective gear to ensure the safety of construction personnel.

Coordination with other trades: During the construction process, the use of steel formwork requires close coordination with other trades such as steel reinforcement workers and concrete workers to ensure smooth progress.

3Material conservation: Use steel formwork reasonably during construction to avoid wastage and damage. For seriously damaged formwork, replace or repair it promptly.

In summary, the correct use of steel formwork is of great significance for improving construction efficiency, ensuring project quality, and safety. During actual construction, adhere to relevant requirements and norms to ensure smooth progress. Continue to summarize experiences and lessons to improve skills, contributing more to the development of the construction industry.