The construction standards for formworks for column primarily include the following aspects:

Ensure that the formwork construction plan and formwork scheduling plan are complete and communicated to the team.

The construction formwork should be fabricated according to the layout dimensions, with the surface height difference between adjacent formworks for column kept within 2mm.

The materials used must meet the requirements of the plan and specifications. The formworks for column should be coated with a release agent, numbered, classified, and stacked. Before secondary use, the formworks for column must be cleaned.

According to the drawings, mark the horizontal and vertical axes, column edge lines, and control lines.

The column axis can be marked with a red “△” symbol with a 50mm side length, along with the words “Axis Line.”

Use a chalk line to mark the column edge line along the design column position. The edge line should extend at least 20cm beyond each end for plumb line checks.

For the column base, chisel off the concrete slurry within the column edge line range until the aggregate is exposed evenly.

The chiseling depth should be no less than 5mm, and the chisel spacing should be controlled between 20mm and 30mm. The chiseling should cover the entire area inside the column edge line.

First, nail down the baseboard at the marked position, and then install the steel column formwork.

Add diagonal bracing at both vertical directions of the column.

Seal the gap at the column base properly. Alternatively, use mortar to seal the outer perimeter of the column base. Avoid using compressed sponge strips or other debris to fill the gaps.

Before checking the verticality, verify the control lines and then proceed with the verticality inspection.

Ensure the seams of the formworks for column are tight, and the height difference between adjacent formworks for column is controlled within 2mm.

When the floor height is ≤5m, the verticality deviation should be controlled within 6mm. For floor heights >5m, the verticality deviation should be controlled within 8mm.

These standards ensure the quality and safety of formworks for column construction and are applicable to various construction projects.

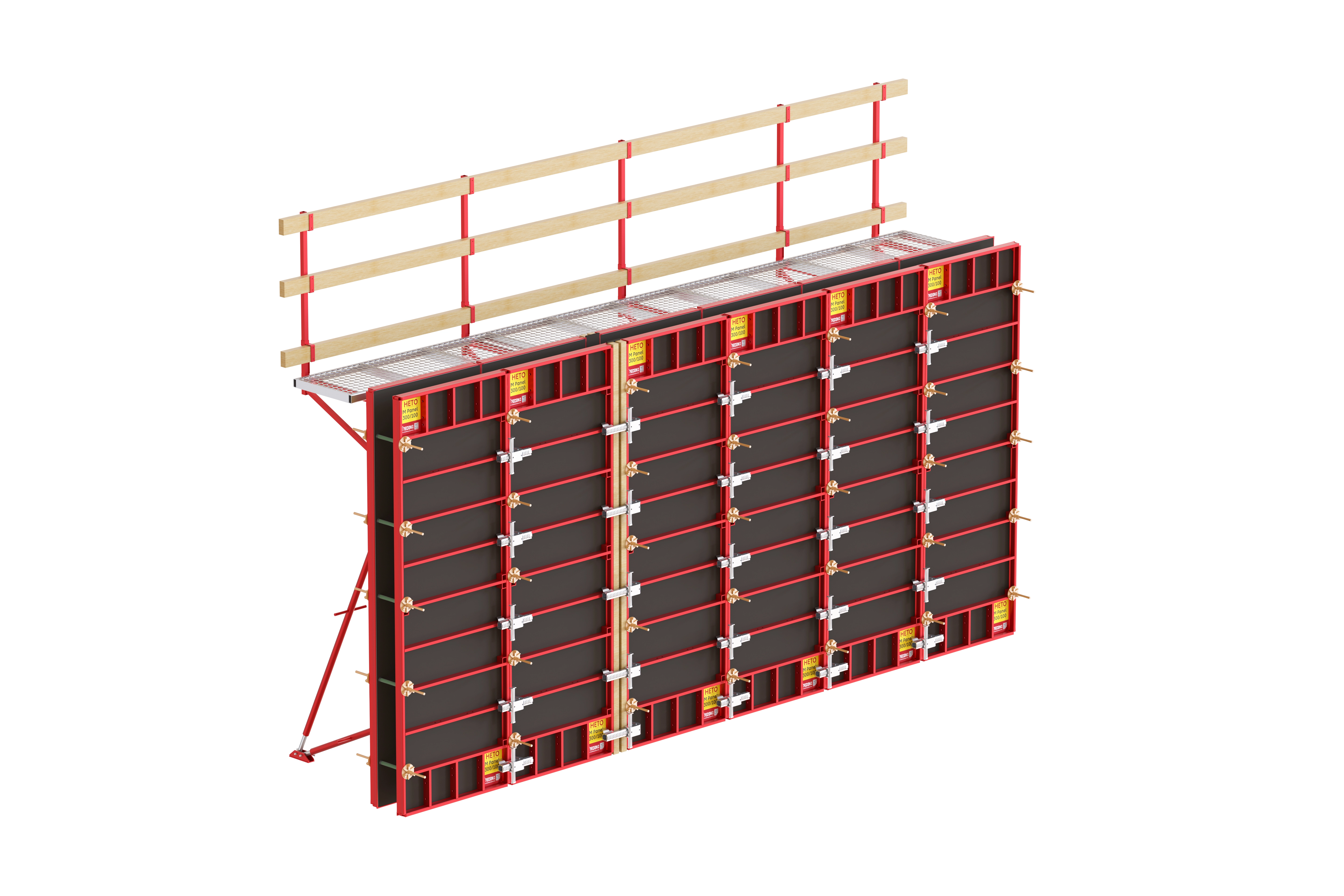

In column formwork construction, standardization not only enhances structural quality but also significantly reduces project timelines. At TECON, we uphold the principles of “Efficiency, Precision, and Safety” by offering a diverse range of formwork solutions, including:

Designed for modularity and rapid reusability, our systems deliver higher productivity and cost savings for projects of all scales.

Choose TECON – Your trusted formwork and scaffolding manufacturer for high-efficiency solutions.