Aluminum alloy formwork is a new type of building formwork technology. Because traditional formwork has its limitations, many architects began to look for a better formwork that can integrate their advantages and avoid their shortcomings to the greatest extent. In view of the fact that a large number of aluminum alloy formworks have been used in the mainland in recent years, it has proved that they can meet this requirement to a large extent, so it has attracted the attention of many people of insight. Next, we will introduce the unique advantages of the aluminum alloy formwork.

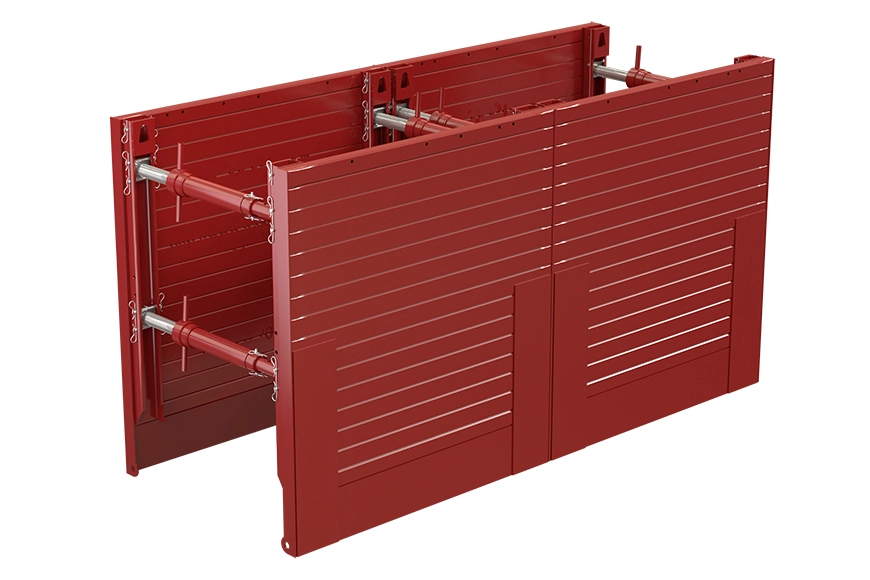

Since the aluminum alloy formwork is made of aluminum alloy material, its surface is usually very smooth and flat. Each piece of the aluminum alloy formwork is processed in the factory with equipment, which can ensure the flatness and quality of the joint. Moreover, each piece is connected by a pin-to-hole connection, as long as the pin is fixed, the connection can be almost seamless. In this way, there will be no leakage of concrete due to too large joints, and no honeycomb pockmark on the concrete surface. Therefore, with the use of aluminum alloy formwork, the look and quality of technically poured concrete can be effectively guaranteed.

Although the purchase price per square meter of aluminum alloy formwork is relatively high, when it is used in buildings with more than 30 floors of standard floors or used repeatedly, we can see that its average use cost is very advantageous compared with other forms.

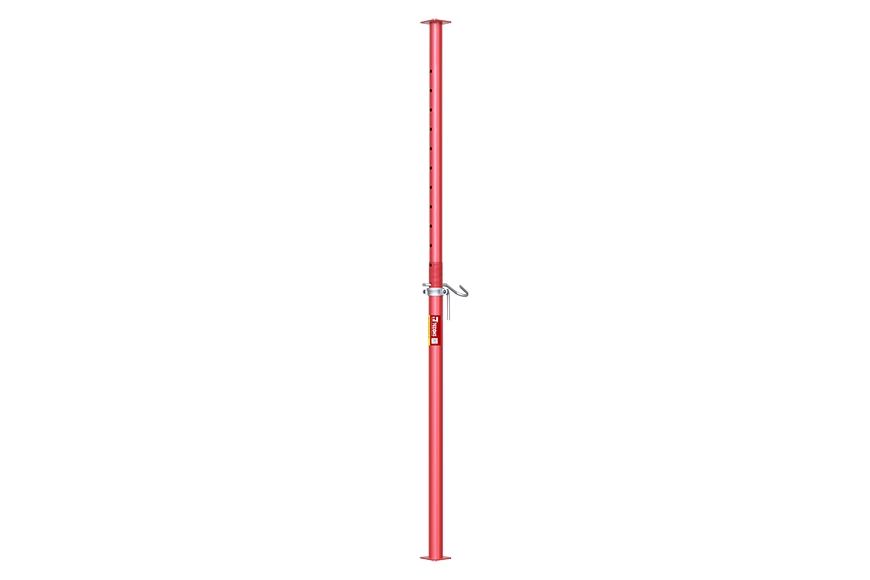

The aluminum alloy formwork technology adopts the "quick demolition system". The so-called "quick demolition system" means that when a certain layer of concrete reaches a certain strength, under the premise of ensuring the safety of construction, in addition to the reserved poles and the support heads, the corrugated bones, formwork, etc. are simultaneously removed and transferred from the material. When transported to the upper floor, the remaining pole must be a stabilizer. The basic principle is to artificially reduce the structural span during the construction phase and reduce its internal force so that the formwork can be removed early without affecting the safety of the structure, so as to achieve the economic and social benefits of the early formwork removal. This quick release system not only guarantees the normal stress requirements of concrete but also breaks through the traditional formwork habits. It greatly improves the efficiency of formwork use and speeds up the construction progress.