1. The advantages of steel formwork

1) The surface of the steel formwork is smooth and shiny.

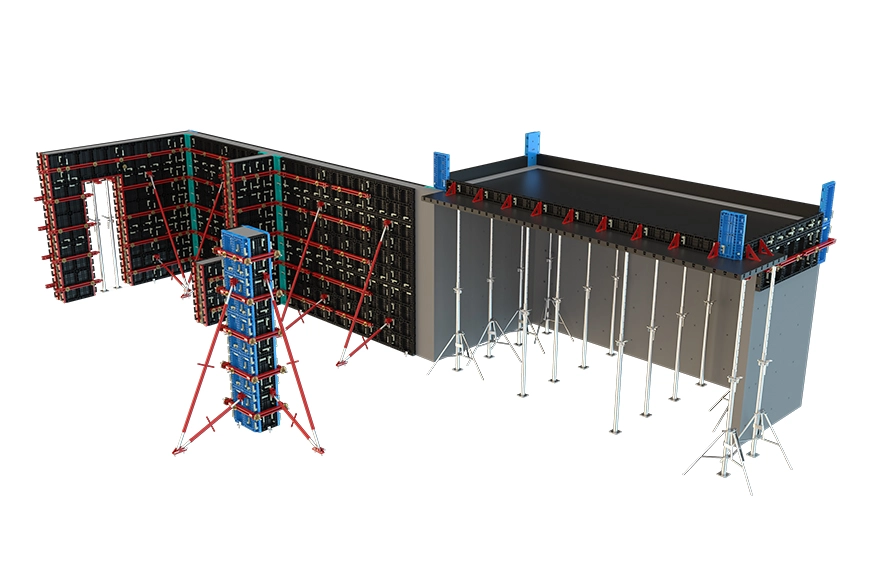

2) The steel formwork has high flexibility, simple splicing and easy assembly.

3) Technological requirements, be strict in strictness, and strive for perfection.

4) It has the reinforcement system, high component strength and high combined rigidity.

5) The plate is made with high precision, tight joints and not easily deformed.

6) The template has good integrity and strong shock resistance.

2. Requirements for substrate treatment before construction of steel formwork

1) No rust: It is necessary to remove the floating rust, welding slag and other paint on the surface of the steel template. When removing the rust of the flat template, we should consider the actual situation of the site, use an angle grinder with a steel wire ball to remove the rust. It is enough to remove the floating rust. It only needs to be treated once. If the rust is severe, the number of treatments can be increased appropriately, but be careful not to make the surface too smooth, which will affect the turnover times of the flat template paint.

2) Oil-free: We need to remove oil, salad oil or other oil stains on the surface of the steel template. The special-shaped template can be removed with a supporting product degreaser or a detergent with strong detergency. The cleaning tools are hard. The floor brushes are divided into small floor brushes and horizontal floor brushes.

3) Cleaning: Before applying the template paint, you need to keep the flat template clean. Some floating dust on the surface can be wiped clean with a dry sponge. For the construction steel template, wipe the surface with cotton cloth and banana water or turpentine water, and dry it with a dry cloth. That is, workers need to bring foot covers when painting, so as not to stain the steel template and affect the effect.