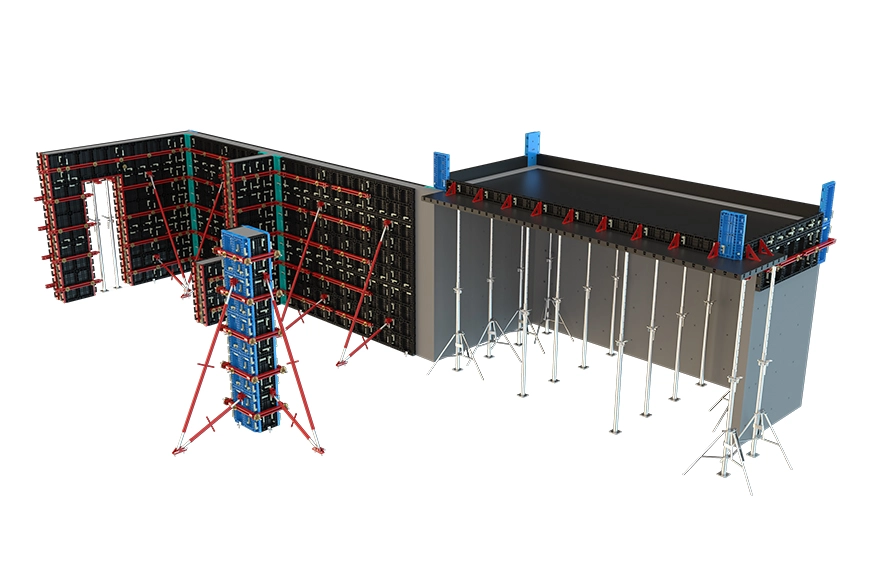

1. The aluminum formwork can be reused and the cost is low: all the accessories of the aluminum formwork system can be reused. The aluminum formwork system is made of 6061-T6 aluminum alloy profiles that are extruded as a whole. A set of aluminum formwork standard construction can be turned over and used more than 300 times, and the use cost is low.

2. The construction efficiency of aluminum formwork is high and the period is short: the aluminum formwork system is a quick-release formwork system, and the formwork can be removed in 18-36 hours. Therefore, only one layer of aluminum formwork and three layers of single support can be used. The normal construction can reach 4-5 days for one layer.

3. There are many different types of formwork in construction, including the aluminum formwork. It has good stability and high bearing capacity: the aluminum formwork system is all assembled with aluminum formwork. After the aluminum formwork system is assembled, it forms an overall frame with good stability and the bearing capacity can reach 60KN per square meter, and there will be no mold expansion accident.

4. The construction of aluminum formwork is convenient and efficient: the assembly of the aluminum system column formwork is simple and convenient, and only the standard plate needs to be increased in proportion during installation. The aluminum formwork is light in weight, 18-25 kilograms per square meter. Relying on lifting machinery and equipment, the installation workers can install 20~30 square meters per day.

5. Aluminum alloy formwork has a wide range of applications: architectural aluminum formwork manufacturers say that the aluminum formwork system is suitable for all building components, such as load-bearing walls, columns, beams, floors, stairs, balconies, etc., which can be completed by cement pouring at one time.

6. After the aluminum formwork is removed from the formwork, the concrete surface effect is good: after the aluminum formwork is removed from the formwork, the quality of the concrete surface is smooth and clean, which can meet the requirements of finishing and fair-faced concrete, without plastering, which can save the cost of secondary plastering.

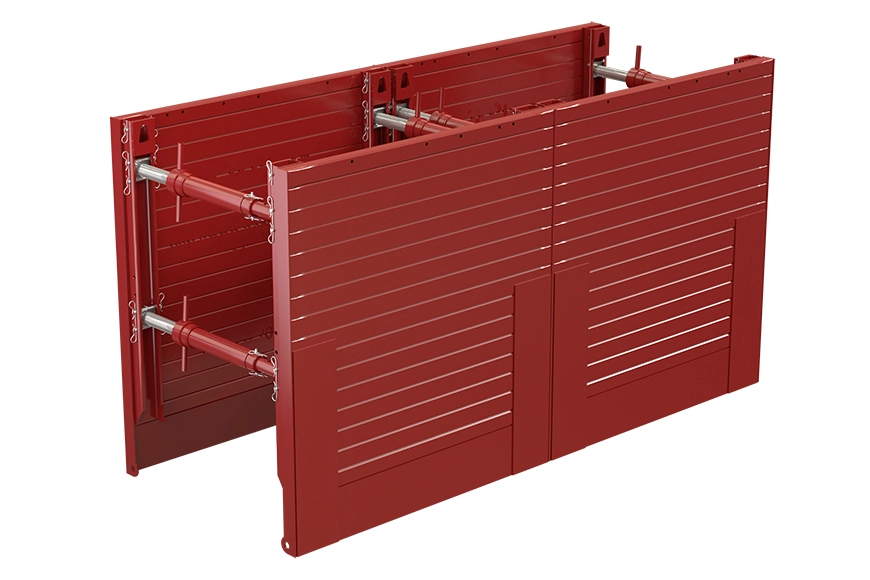

1. Hardness

Many customers are very concerned when purchasing aluminum, and the hardness is directly related to the chemical composition of the alloy. Secondly, different states also have a greater impact. From the point of view of the hardness that can be achieved, the 7 series, the 2 series, the 4 series, the 6 series, the 5 series, the 3 series, and the 1 series decrease in turn.

2. Strength

The strength of aluminum alloy formwork is an important factor to be considered in product design, especially when aluminum alloy components are used as components, appropriate alloys should be selected according to the pressure they are subjected to. Pure aluminum has low strength, while 2-series and 7-series heat-treated alloys have higher strength, and there is a certain corresponding relationship between hardness and strength.

3. Corrosion resistance

The corrosion resistance of aluminum alloy formwork includes chemical corrosion, stress corrosion resistance and other properties. Generally speaking, 1 series pure aluminum has higher corrosion resistance, 5 series performs well, followed by 3 series and 6 series, and 2 series and 7 series are poor. The selection principle of corrosion resistance should be determined according to its application. High-strength alloys are used in corrosive environments, and various anti-corrosion composite materials must be used.

4. Processability

The processing performance of aluminum alloy formwork includes formability and cutting performance. Because the formability is related to the state, after selecting the aluminum alloy grade, it is also necessary to consider the strength range of various states. Usually, materials with high strength are not easy to form. For bending, drawing, deep drawing and other forming processes of aluminum, the formability of the material in the annealed state is good, on the contrary, the formability of the material in the heat treatment state is poor.