With the development of construction industrialization and the continuous improvement of the technical level of bridge formwork, the promotion and application of bridge formwork has been continuously improved. However, when using bridge formwork, we should also pay attention to a series of problems, especially after the construction is completed, we should pay attention to the following items:

1. Data collection, collection, arrangement and on-site verification of bridge formwork.

2. Check the support for corrosion, aging, displacement, etc.

3. Check whether the piers and foundations are slippery, inclined or sinking. Whether the concrete table cap is weathered, cracked, peeled, exposed, etc. Whether the top surface of the pier is clean, and whether there is water leakage at the expansion joints. Whether the cone slope is in good condition, whether there are joints falling off, whether the cut pieces are loose or missing, and whether there are through cracks.

4. Whether the concrete is cracked, defective and corroded, whether there is overall cracking caused by alkali aggregate reaction, whether there is serious carbonization on the surface, and whether the beam body has obvious displacement and deformation.

5. Whether the bridge formwork, like bridge pier formwork, is flat, straight and flexible, whether there is abnormal deformation and noise, looseness, damage, falling off, water leakage, whether it is embedded with debris, whether the pavement layer of the groove is gnawed, and whether it causes obvious jumping.

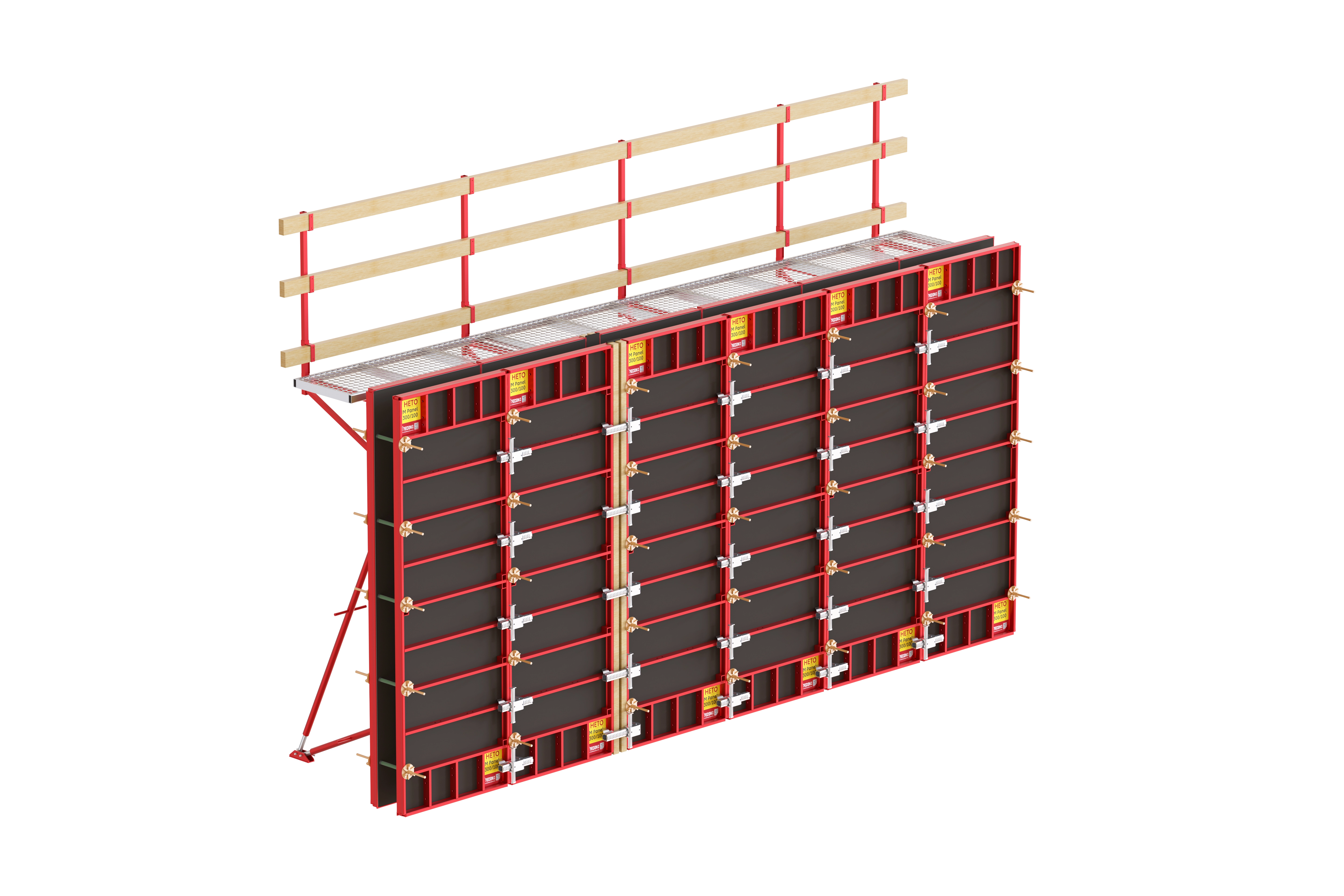

The use of construction formwork accessories of bridge shuttering and formwork supports has realized an important measure of "replacing wood with steel", which is also a major reform of concrete construction technology.

As a tool for forming concrete members, the bridge formwork itself should not only have the same shape and size as the structural members, but also have sufficient strength and rigidity to withstand the load of newly poured concrete and construction load. Therefore, judging whether the bridge formwork is qualified depends on whether the following four conditions are met:

1. The seams are tight and do not leak.

2. It is easy to assemble and disassemble and can be used many times.

3. Have sufficient strength, stiffness and stability.

4. It can ensure that the shape and size of the structure and components are accurate.

Therefore, it is necessary to be careful and careful when designing bridge formwork, and design it reasonably according to the conditions and standards.