(1) Set up small steel molds, but they are not set up in accordance with the regulations, resulting in poor overall performance of the building.

(2) The foundation of the formwork is not strong, the building formwork is not placed at a level, and the waterproof measures are not done well.

(3) When using wooden building formwork or plywood, after the formwork is built, the concrete cannot be poured in time, and long-term sunlight and rain will cause deformation.

(4) The support spacing is too large, and the steel plate has poor rigidity.

(5) The speed of pouring concrete or column concrete is too fast, the height of one pouring is too high, and the vibration is too large.

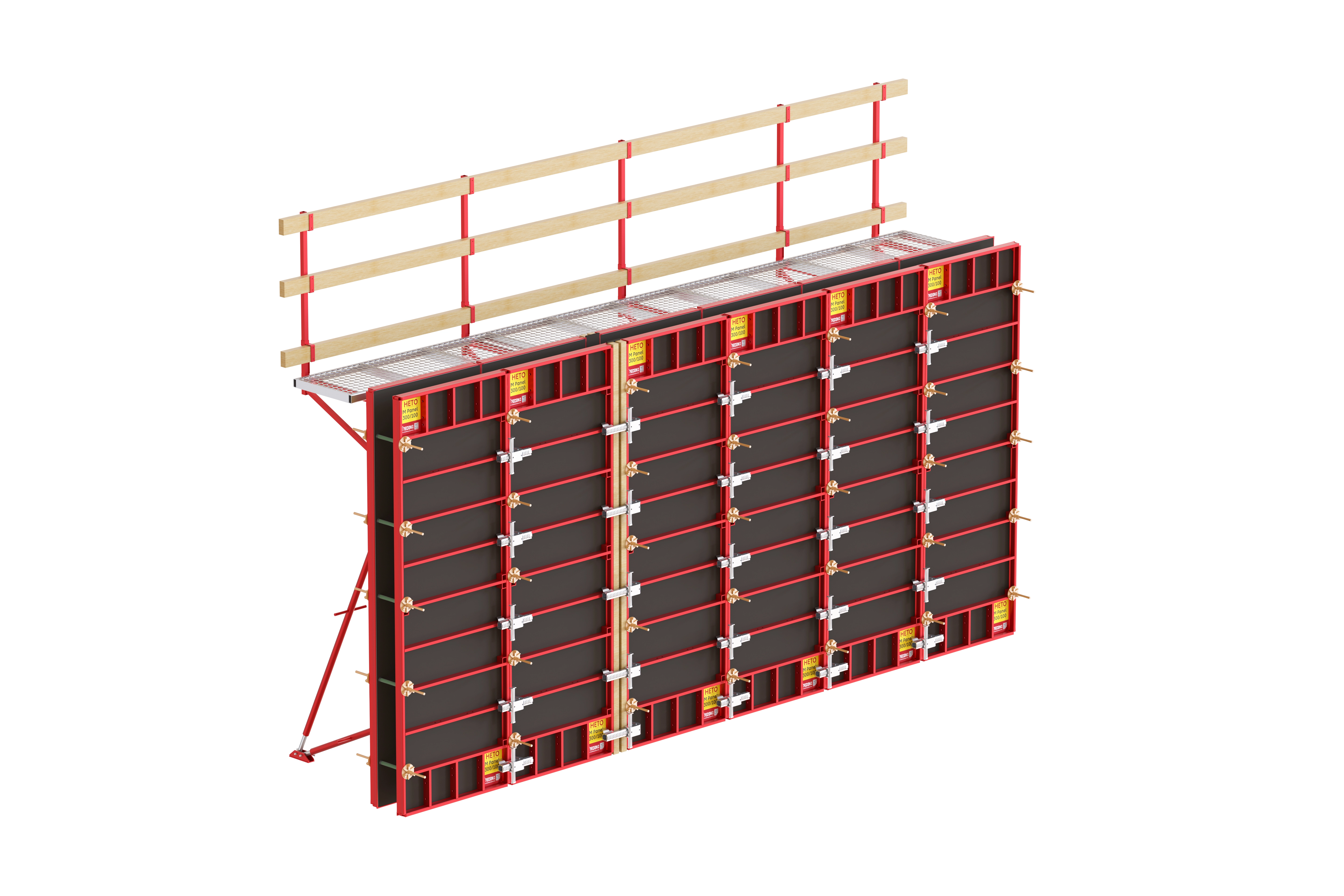

(1) When using the building formwork and its supporting system, the construction personnel must fully consider their own weight, rated load, and the lateral pressure generated by the concrete during the pouring process to ensure that the formwork has sufficient load capacity during use.

(2) When assembling small formwork, the joints should be placed in accordance with the regulations. The spacing and specifications of the cofferdam and the tightening bolts should be set according to the design requirements.

(3) If the formworks for beam and column use cassettes, the spacing should be specified and the building formwork should be clamped, and its width should be slightly smaller than the section size. The upper part of the building formwork for beams and walls must have temporary support heads to ensure the width of beams and walls when concrete is poured.

(4) When pouring concrete, it should be uniform without unloading, and the pouring height should be strictly controlled, especially on both sides of the building formwork at the door and window openings. It is necessary to ensure that the concrete is vibrated and dense, but also to prevent its excessive deformation, which may cause the deformation of the building formwork.