The height of the existing steel formwork is designed according to the conventional standard, and the thickness of the formwork is reduced as the basic size. The problem of different floor heights is solved by temporarily increasing the upper jointed board, resulting in different heights and dimensions of the upper jointed boards. In addition to cast-in-place concrete projects for buildings, municipal projects such as steel formwork for overpass bridges and subway walls also tend to expand the use of large-scale steel formwork. In order to meet the requirements of this new trend, there should also be a major breakthrough in the way of heightening the steel formwork.

At present, all cast-in-place concrete projects should be equipped with large steel formwork in addition to the standard floor, and most of the basement and equipment floor should be equipped with corresponding large steel formwork according to the requirements of the project.

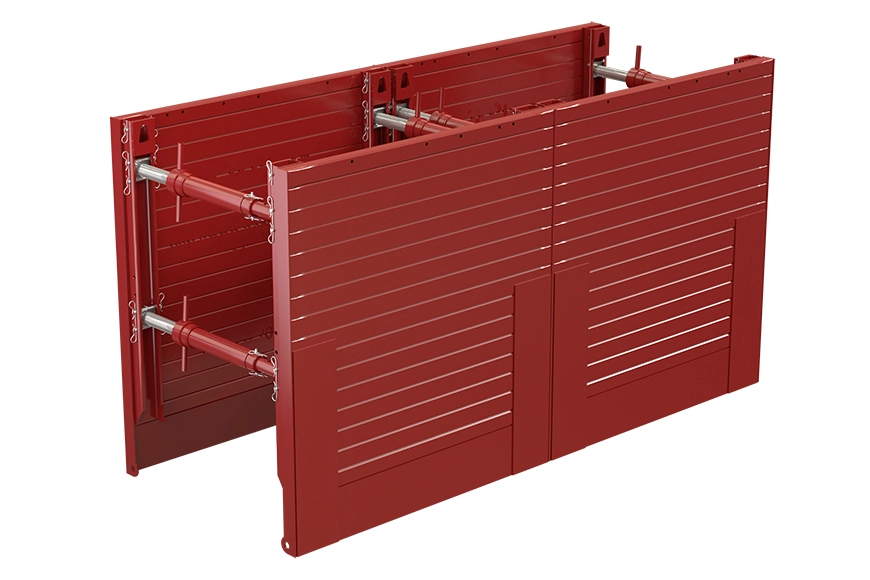

At present, the structural strength calculation of large steel formwork is designed with a concrete pouring height of about 3 meters, that is, the concrete side pressure that the formwork can withstand is about 60KN/M2. When the concrete pouring height is greater than 3 meters, most of the lateral pressure of the concrete on the steel formwork is greater than the ceiling value. That is to say, when designing the steel formwork, it should be considered that the main back arris should be densified when necessary, the distance between the through-wall bolts should be reduced. In order to improve the ability of steel formwork to resist concrete lateral pressure, the number of through-wall bolts should be increased, so as to meet the construction requirements of tall wall concrete.

In the design of the steel formwork structure, the size change and installation of related accessories such as outriggers and platform frames at different steel formwork heights should also be considered to meet the support formwork requirements. It is urgent to improve the applicability of steel formwork in different types of projects and different parts of cast-in-place concrete wall projects. Solving this problem will create considerable economic benefits for the construction unit and create good social benefits for the society.

With the rapid development of China's economy, urban transportation, expressways, railways, etc., the construction of many expressways have increased the demand for bridge steel formwork, and the steel formwork market has a bright future.

Advocating and encouraging the production and use of bridge steel formwork so as to replace wood formwork is not only in line with national conditions, but also in line with technological progress and market needs. At the same time, it is also a responsibility and manifestation of China's active protection of the world's natural environment. Steel formwork technology also directly affects the quality, cost and benefit of engineering construction, so it is also an important content to promote the progress of construction technology.

In the construction industry, every small difference may lead to the failure of the entire project. Bridge steel formwork is also an important part, which has an important impact on the quality control of the project. Therefore, the production of formwork should be based on strict production technology control. It's necessary to improve the production technology in the links of raw materials, gluing, hot pressing and trimming, and strictly ensure the production quality and use quality of steel formwork.