A working platform should be erected before demolition to ensure stability;

The concrete strength needs to reach the design allowable value before formwork demolition;

Avoid loosening and colliding with support rods when removing formworks;

Clean the dirt on the formwork immediately after removing it, and brush the release agent in a timely manner.

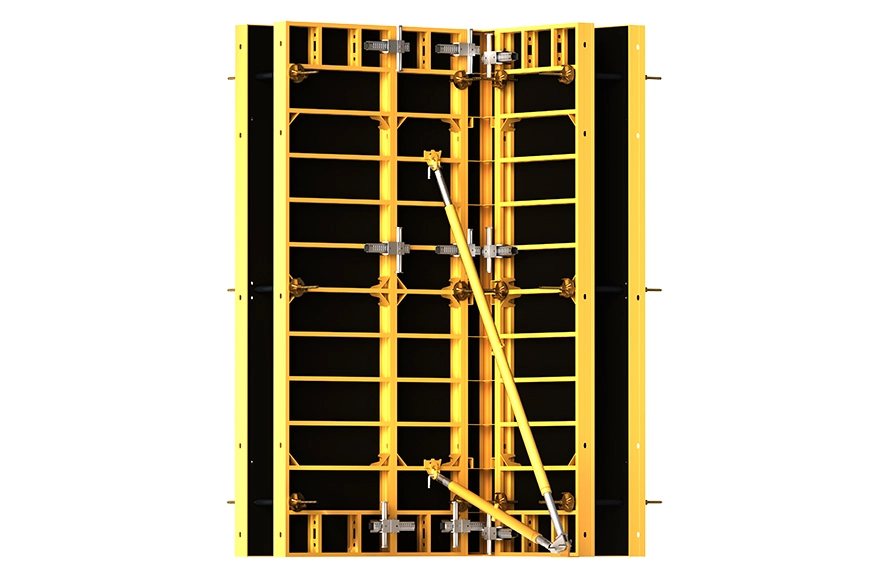

Removing the side formwork of the wall and column

In general, the formwork on the side of the wall and column can be removed 12 hours after the concrete pouring is completed. First, remove the diagonal support, then remove the through-wall bolts. When removing the through-wall bolts, use a wrench to loosen the nuts, take off the washers, remove the back ribs, tap one end of the bolt lightly until the bolt exits the concrete, and then remove the connecting pins of the formwork. Use a crowbar to move the formwork away from the wall, remove the aluminum formwork and accessories, and clean them, then move them to the same position on the upper floor and stack them flat.

Removing the top formwork

In general, the top formwork can be removed after 48 hours. Start removing the beam and plate support rods and their connecting parts, and then remove the connecting pins of the beams and plates adjacent to them. Then the formwork can be removed, use a crowbar to pry it off from the interface between the formwork and the concrete, and ensure that the support rod remains in its original position and is not loose when removing.

Remove the support rod

The dismantling of aluminum formwork system support rods should meet the requirements of concrete strength when removing the bottom formwork. The dismantling time of the support rod should be determined based on the retained demoulding test block.

In general, the bottom support can be removed 10 days later, the beam bottom support can be removed 14 days later, and the cantilever beam support can be removed 28 days later. When removing each support, hold the support rod with one hand, use a hammer to hit the adjustable fulcrum in the loosening direction, and then the support rod can be removed.

As one of the leading experts in the field of formwork and scaffold engineering, our extensive range of ready-made and custom products ensures that we can provide solutions for your construction project, no matter how big or where it is.

With the professional R&D team and experienced technical team members from our formwork company, we will provide you with assistance on site when necessary, and you can rest assured that our solutions are always cost-effective. From the first contact to the completion of construction, we will always be there to support you. Welcome to inquire.