1. Inspection of the bridge deck structure of the bridge formwork:

Whether the longitudinal and transverse slopes of the pavement layer are smooth, whether there is peeling and exposed skin, loose aggregates, oil flooding, severe cracks (net cracks, longitudinal and transverse cracks), broken, pits, caves, waves, and water leakage from the waterproof layer.

Whether the bridge shuttering is flat, straight, and flexible, whether there is abnormal deformation and noise, looseness, damage, falling off, water leakage, whether it is embedded with debris, whether the notch pavement is gnawed, and whether it causes obvious jumping.

Whether the anti-collision wall and anti-collision pier are complete, reliable, without collision, fracture, dislocation, looseness, missing parts, corrosion, peeling, etc.

Whether the sidewalk is complete, whether there are serious cracks (net cracks, vertical and horizontal cracks), broken, incomplete, collapsed.

Whether the bridgehead is smooth and whether the back of the platform is sinking.

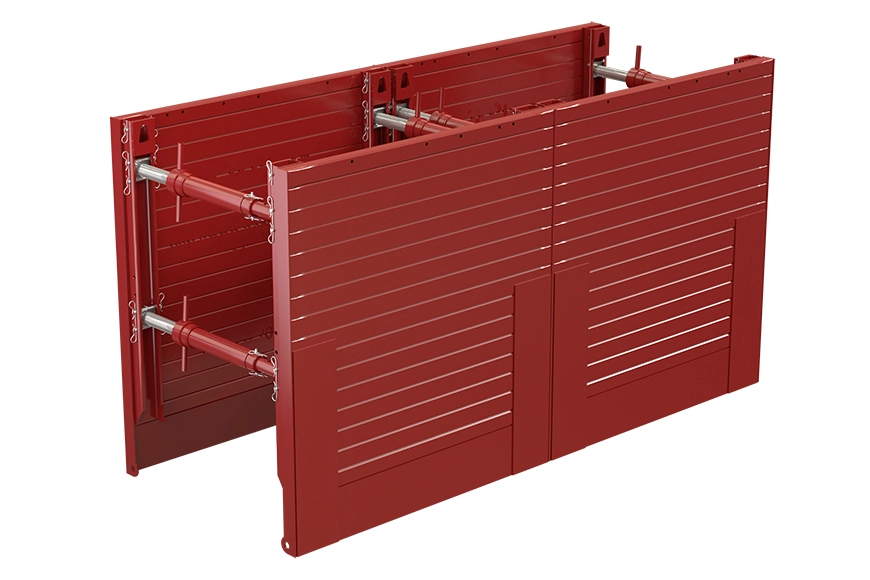

2. Inspection of reinforced concrete beam bridge formwork:

Whether the beam end and bottom surface are damaged.

Whether the concrete has cracks, water seepage, honeycomb, voids, spalling, exposed tendons and corrosion, and whether there is overall cracking caused by alkali aggregate reaction. Whether there is severe carbonation on the concrete surface.

Whether the concrete is cracked, chipped and corroded. Check whether the transverse connecting members are cracked, and whether the side beams are laterally shifted or inclined outwards. Whether the beam body has obvious displacement and deformation.

3. Inspection of bridge formwork piers and foundations:

Whether the piers and foundations slip, tilt or sink. Whether the concrete table cap is weathered, cracked, peeled, exposed, etc. Whether the top surface of the pier is clean, and whether there is water leakage at the expansion joints. Whether the cone slope is in good condition, whether there are joints falling off, whether the cut pieces are loose or missing, and whether there are through cracks.

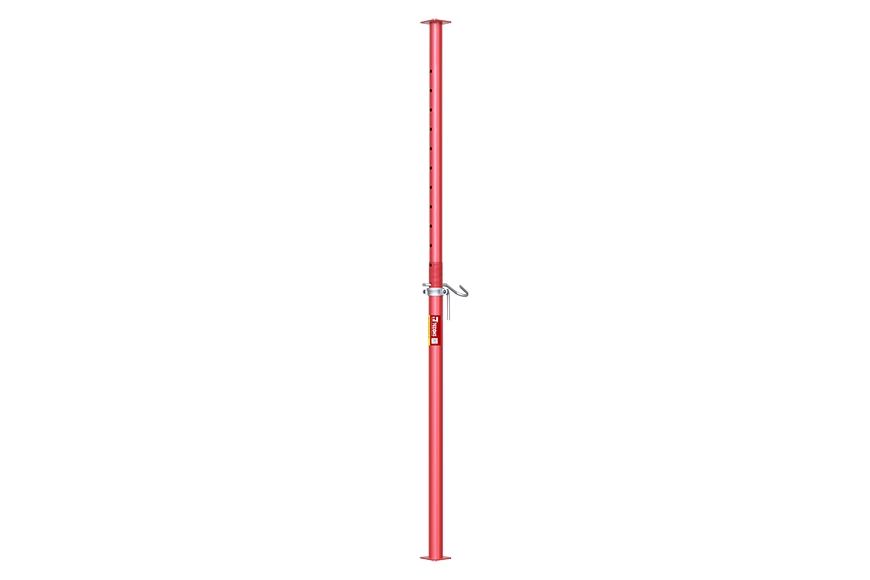

4. Inspection of bridge formwork supports

Whether the supports are corroded, aged, displaced, etc.

5. Data collection, collection, arrangement and on-site verification of bridge formwork

6. Evaluate the technical condition of the bridge formwork according to the test results

The evaluation criteria are divided into five grades: A (good), B (good), C (qualified), D (failed) and E (dangerous).

With the expertise of the TECON R&D team, our technical team members are there to assist you when necessary, and knowing that our solutions are always cost-effective, you can be confident that from the first contact to the completion of construction, we will always be there to support you. Welcome to consult.