(1) Good safety performance

1. Wooden springboards are easy to crack, corrode, and burn, and are prone to safety accidents. The angle steel mesh plate is rusted and peeled off, and the hot-dip galvanized steel formwork has the advantages of anti-corrosion and fire-proof.

2. The steel formwork has standardly formed convex holes, with high anti-skid coefficient and good effect. The bow-shaped design on both sides of the formwork and the firm welding of the bottom rib plate further increase its strength. The 3-meter-long scaffolding board can withstand the standing of 5-6 people at the same time without deformation, and is sturdy and durable.

(2) long service life

The wooden springboard can no longer be used safely and continuously after 3-5 turnovers, and the steel shuttering is also vulnerable to rust and deformation. The hot-dip galvanized steel formwork has high strength, no corrosion and no deformation, and its normal life is about 6-8 years.

(3) Easy and fast installation

For the same scaffolding board, the weight of the wooden springboard is 1.5-2 times the weight of the steel scaffolding board, and the wooden board is heavier after absorbing water in rainy days, and it is extremely non-slip. During the construction of workers' novels, two people are required to lift and transport the wooden boards, while one person can carry 2-4 pieces of steel formwork, which greatly improves the work efficiency, and the high strength reduces the number of scaffolding tubes used.

The steel formwork is properly maintained and can be used for a long time. It is suitable for flat formwork of different project scales, structural forms and construction processes.

Repair and maintenance of steel formwork: Steel formwork is not as convenient as bakelite formwork during operation, especially for drawing rods, the symmetry error should not be too large. Operators sometimes encounter situations where the lead rod cannot pass through. Punching holes in the formwork will affect the value of steel formwork recycling over time.

However, it is not difficult to find a steel formwork that is 20 to 30 centimeters smaller than the hole to be embedded in the hole and parallel to the surface of the board. Then, after welding it, level it with a hand grinding wheel and cut off the excess on the back. Both flat and bright.

After the steel formwork is used up, do not stack it in the field. It should be transported back to the warehouse in time to remove the cement impurities and rust spots on it, polished it with a grinder, and brushed with a layer of engine oil (it is better to add a small amount of diesel in the engine oil) and stack it neatly.

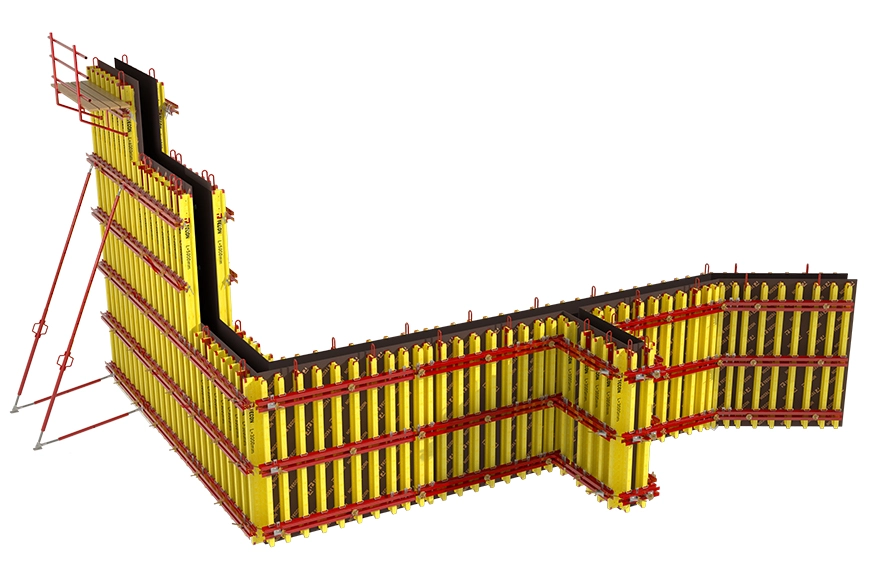

Combined steel formwork is a concrete structure mold system composed of shaped plates, special-shaped formwork connectors and supports. Combined steel formwork has the following advantages over aggressive wood formwork and old-style steel formwork:

1. The production precision is high, the joints are tight, the rigidity is large, and it is not easy to deform. The concrete structure formed by the square column formwork is accurate in size, dense and smooth.

2. High combined rigidity: The plates are arranged with staggered joints. The panels formed by the bridge formwork have the overall rigidity of the plane. The column-beam formwork itself is a load-bearing component, which can improve the overall rigidity, facilitate the overall hoisting, and simplify the support structure.

3. Long service life: The components have high strength and durability, and can quickly turn around and repair building templates in time.