The ringlock scaffolding system, with its advantages of high strength, strong stability, and convenient assembly, is widely used in bridge engineering, viaducts, tunnel engineering, plant construction, elevated water towers, power plants, refineries, and other large construction projects. Additionally, this system is suitable for pedestrian overpasses, span shelves, storage shelves, chimneys, water towers, interior and exterior decoration, and other scenarios.

Furthermore, ringlock scaffolding is also extensively applied in temporary construction projects such as large concert stages, background frames, grandstands, viewing platforms, modeling frames, staircase systems, and sports event grandstands.

Multi-functionality

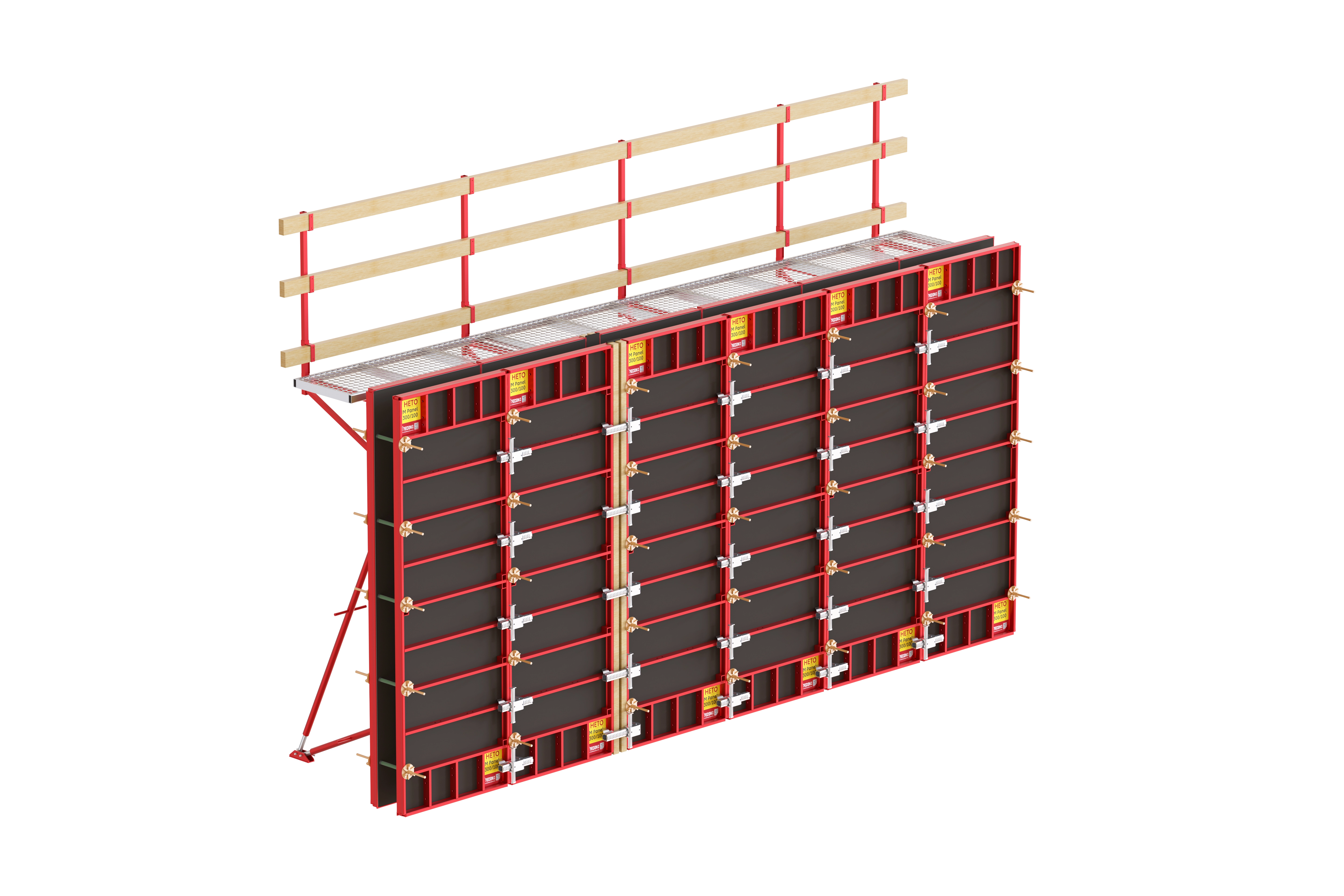

The ringlock scaffolding system can be assembled into various construction support structures such as single-row, double-row scaffolding, support frames, support columns, material hoists, etc., according to different construction needs. It can also be arranged in curves. Its flexibility allows it to adapt to complex construction environments, such as:

Can be erected on uneven slopes or stepped foundations;

Can support stepped formwork, allowing for early removal of formwork;

Can build passageways, cantilevered wings, and other special structures;

Can be integrated with climbing frames, mobile work platforms, and exterior scaffolding systems to enhance safety and applicability;

Can be used as storage racks, advertisement stands, large stage setups, and other non-construction applications.

Simple Structure

The ringlock scaffolding system consists of three main components: vertical rods, horizontal rods, and diagonal rods. All parts are prefabricated in the factory, effectively reducing the loss of traditional scaffolding's loose components and lowering the economic loss for construction units.

Compared to traditional coupler scaffolding, the ringlock scaffolding system has no loose locking parts, thus avoiding safety hazards caused by loose couplers and making the overall structure safer and more stable.

High Economy and Quick Installation

The ringlock scaffolding system adopts a wedge pin connection method. By aligning the plug at both ends of the horizontal rod with the tapered hole on the vertical rod and gently tapping, the assembly is fixed, making the setup fast and easy;

Its assembly and disassembly speed is 4-8 times faster than coupler steel pipe scaffolding and more than 2 times faster than cup lock scaffolding, effectively reducing construction time and labor costs;

The weight of vertical rods is 6-9% lighter than the same specifications of cup lock rods, making transportation easier and construction more efficient.

High Load Capacity and Stable Structure

The vertical rods of the disk lock scaffolding adopt axial force transmission, forming a high-strength structure in three-dimensional space, with stability far exceeding traditional scaffolding. Compared to cup lock scaffolding, its overall structural strength is increased by 20%.

Each vertical rod can bear a load of 3-4 tons, meeting the heavy load construction needs for high-rise buildings and bridges;

Disk lock round disc nodes provide reliable axial shear resistance, ensuring the scaffolding remains stable and reliable under high loads.

Safe and Reliable, High Stability

Uses an independent wedge inserted self-locking mechanism, ensuring that even if the pin is not fully tapped, the horizontal rod plug will not fall off;

The connection method has a self-locking function, enabling easy pressing to lock or pull out to disassemble, making operation convenient;

The axial lines of the vertical rods and horizontal rods intersect perpendicularly with high precision, ensuring reasonable stress distribution and preventing skew, further enhancing stability.

With its high load capacity, quick installation, safety, stability, and multifunctional adaptability, the ringlock scaffolding system has become the preferred support system for modern construction projects in buildings, bridges, stages, sports venues, etc. Compared to traditional coupler and cup lock scaffolding, the disk lock scaffolding demonstrates significant advantages in construction efficiency, safety, and economy, and its application in the construction industry is set to become even more widespread in the future.