(1) According to various market surveys, China consumes about 570 billion worth of building formwork every year. Steel formwork, wood formwork and aluminum formwork still account for the vast majority of the market, while plastic formwork accounts for only 5% of the market. The market potential is huge.

(2) Plastic formwork is required for expressways, urban roads and bridges, water conservancy projects, etc.

(1) At present, wood formwork is still the mainstream in the market. Wood formwork needs a lot of wood, and the scrap residual value is very low. Deforestation is required, which is contrary to the global climate protection initiative. It is not easy to demould. It needs to brush release agent. There are many residual nails and spikes on the construction site, which is easy to cause casualties.

(2) Steel formwork is also widely used in the market. Steel formwork has strong compression and bending resistance, but due to its high cost, it is generally only used in some specific buildings. Moreover, the steel formwork is bulky and requires large machinery for hoisting construction. The construction efficiency is very low and the scrap salvage value is not high.

(3) In recent years, the performance of aluminum mold is not much different from that of steel mold, and the cost is also very high. Generally, it is mainly rented, and the release agent also needs to be used for demoulding.

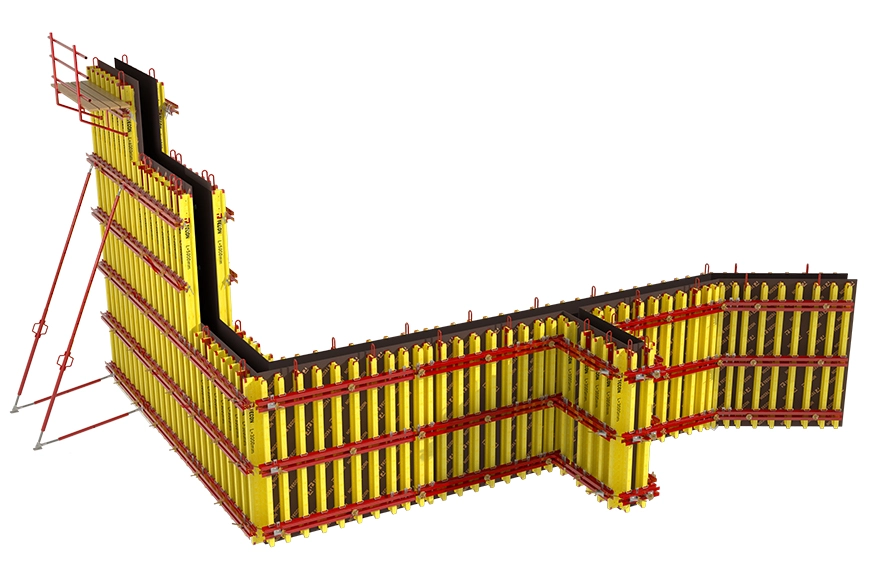

(4) Now some projects use aluminum frame plastic mold to replace aluminum mold, the cost is lower than aluminum mold, no release agent is required, and leasing is also the main method.

(5) Plastic shuttering panels are mainly divided into ribbed formwork and hollow formwork, which are famous for their portability, environmental protection, high construction efficiency and high recycling value. Ribbed plastic templates (taking quick and easy plastic molds as an example) are famous for their strong compression and corrosion resistance, convenient disassembly and assembly, and its ability to reach more than 300 turnover times. The hollow plastic formwork is flexibly used and can reach more than 50 turnover times.

(1) In recent years, with the gradual rise of plastic templates, there are many imitations in the market. they have no technical support, and the core formula is not up to standard, and there are many problems in their marketing mode, such as inconsistency between pre-sales and after-sales, which need to be improved.

(2) At present, even if all the plastic formwork equipment and machines in the industry are fully powered and produced 24 hours a day, it can have an annual sales of about only 8 billion, which is far from the 570 billion market.

(3) Only by adhering to the principle of quality first, constantly improving the formula, obtaining national quality certification and patent recognition, constantly improving the construction technology and meeting the needs of different customers can we go further.

(1) With high one-time investment, many construction merchants began to flinch and dare not take this risk.

(2) It has been confirmed in many aspects that some large enterprise builders tend to purchase plastic formwork, and can accept replacing steel formwork, wood formwork and aluminum formwork with plastic formwork.

(1) It is understood from many aspects that at present, some financial enterprises and large enterprises have begun to understand and pay attention to the plastic formwork market, and are waiting for further investigation.

(2) In many bidding documents, it has been clearly indicated that plastic formwork must be used for construction. Slowly, everyone began to accept and approve the plastic formwork.

(3) According to the current development trend, a number of large plastic formwork enterprises will be achieved in the next 3-5 years.

(4) As long as the production enterprises control the quality standards and later services, the future will be bright. If they innovate in the construction processes such as assembly and reinforcement, they will reach a higher level.