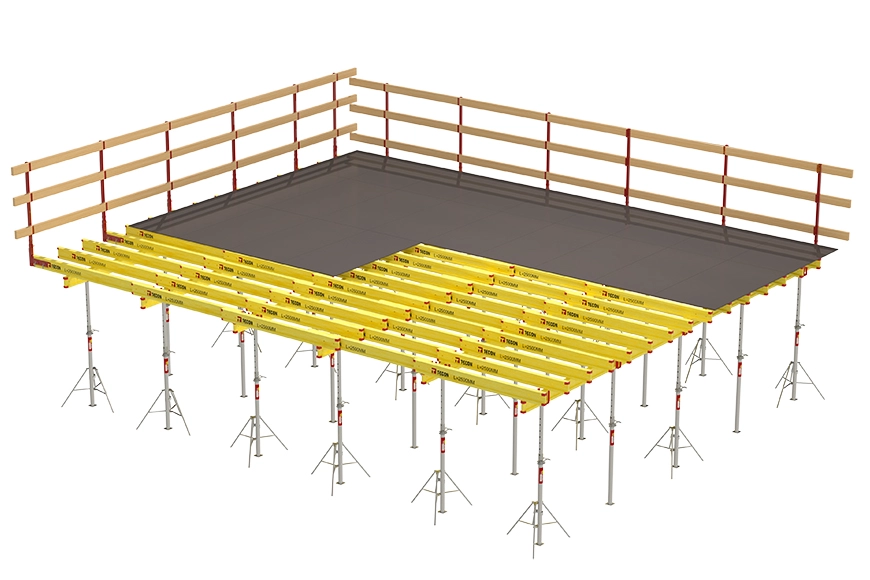

Steel formwork is composed of formwork surface structure, support system, operating platform and accessories. It is a tool formwork for the construction of cast-in-place wall and wall structure. Its characteristic is that the bay, depth and floor height are the size of large formwork.

(1) Light weight and large width of formwork. It's weight can be reduced by 1/4 to 1/5 compared to that of the combined steel formwork. The width of steel formwork can be enlarged, reducing the joints of the steel formwork assembly.

(2) The amount of steel used is reduced, which can be reduced by 1/2 compared to the combined steel formwork.

(3) The adsorption force of the steel formwork is small and it is easy for formwork removal.

(4) There are many turnover times. Generally it can be used for 50 times.

(5) The steel formwork has good thermal insulation performance, which is conducive to the thermal insulation of concrete in winter.

(6) The steel formwork is easy to maintain, and the local damaged surface can be repaired on site. When one side is worn out, it can be turned over for use.

Reinforcement system, high component strength, high combined rigidity, high manufacturing precision of formwork blocks, tight joints, not easy to deform, good integrity of the steel formwork, and strong seismic resistance.

Steel formwork is used for concrete casting. In addition to steel formwork, there are wooden formwork, plywood formwork, etc. Steel formwork is widely used in construction projects because of its multiple use and beautiful appearance of concrete casting.

(1) According to the purpose of steel formwork, it can be divided into: civil construction (house construction) steel formwork and bridge steel formwork.

(2) According to the pouring shape of the steel formwork, it can be divided into: box girder formwork, T-beam formwork, cover beam formwork, hollow beam formwork, round formwork, protective beam formwork, pier column head formwork, etc.

There is also a combined steel formwork which is divided into: large formwork, small formwork, medium formwork, internal corner, external corner and so on.

During the construction of the composite steel formwork, attention should be paid to safe construction. The following matters need to be paid attention to during the installation process of the composite steel formwork:

(1) The steel uprights are assembled in the order of the matching formwork design to ensure the overall stability of the formwork system.

(2) The fittings must be installed firmly, the supporting surface under the pillar and the diagonal brace should be flat and solid, and enough compression area is needed, and the support should focus on the outer corrugation.

(3) The embedded parts and reserved holes must be located accurately and installed firmly.

(4) The bottom surface of the wall and column formwork should be leveled, the lower end should have a reliable support point, and the straightness should be corrected.

(5) The horizontal brace and scissor brace of the steel formwork pillars should be arranged according to the structure and overall stability.

(6) The pillars of multi-layer support are set on the same vertical centerline and the upper part should be corresponding to the lower part.

(7) The wooden flute should use the whole rod, the joints should be staggered, and the overlap joint length should not be less than 200mm.