aluminium formwork manufacturers suggest to make an overall plan before construction. In addition to the coordination of various units involved in the construction, the more important thing is the deployment and operation of construction tools and materials. aluminium formwork is an important construction tool. The main body of building construction is basically completed by aluminium formwork. Of course, the risk of engineering projects still needs to be considered, including various factors such as delays in the construction period, problems of workers, the satisfaction of materials, the danger of construction, and so on.

The construction of aluminium formwork is a particularly worrying operation, because a large building or a super large building can meet the needs not only by completing the construction of the entire concrete shelf, but the function of a large building is a very important part of the construction. The pre-embedding in the construction of aluminium formwork is the performance of the function of the building. In the construction of the entire construction project, it is still more important to grasp the rhythm of the construction and be orderly, even if it is appropriately difficult.

These problems that may be encountered in the construction must be taken into account. After all, a large-scale project still needs to make a close and feasible construction plan. Although the unexpected situation may disrupt the plan, the aluminium formwork manufacturer has no plan, isn't it? It is more messy, so do every step well to ensure the smooth progress of the construction.

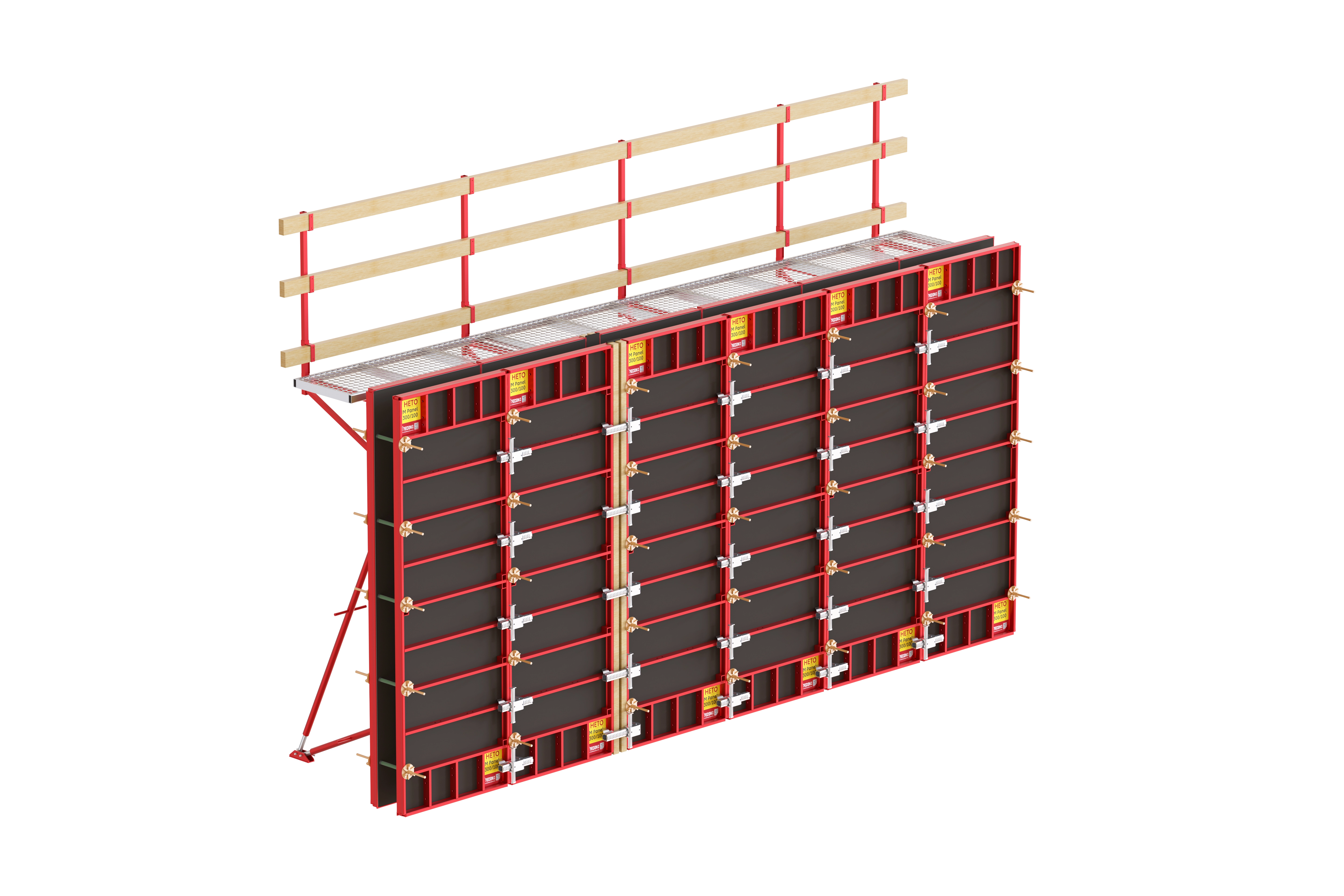

Aluminum alloy formwork is not only green, but also the process of its establishment is very simple. The traditional formwork construction period is long, the site is dirty, messy, and noisy, a lot of construction waste occurs, the resource consumption of building materials is large, the cost of manpower is high, and the quality of construction is difficult to guarantee.

Compared with the traditional construction method, the floor using the aluminum alloy formwork can be cast and formed as a whole, with better flatness and verticality, the surface is smooth and free of plastering, and it can be reused more than 300 times. This can not only save a lot of manpower and material resources, but also can be recycled, energy saving and environmental protection, and the economic benefits are obvious. Now, aluminum alloy formwork has gradually been widely used in the construction of various buildings.

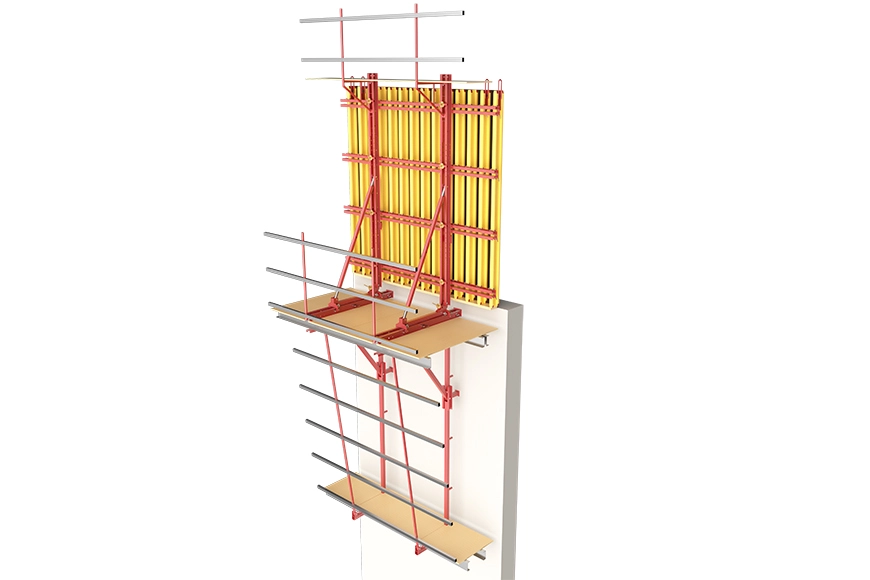

The aluminum alloy formwork is modularized and produced by the factory. It is assembled on site by professional technicians. After the concrete is poured and formed, the formwork can be removed, and then the effect and efficiency of "building a house like building blocks" can be achieved.

When the aluminum alloy formwork is stored, it should satisfy the self-stabilizing angle required by the regional conditions. The two aluminium formwork should be stored in a board-to-board surface. If the aluminum alloy formwork is stored for a long time, it is necessary to replace the aluminium formwork with a whole. The purpose is to prevent the deformation of the formwork support system in the later stage.

However, if it is stored on the construction floor, there must be reliable anti-dumping measures. If there is no support, it can be placed flat or on a special stacking rack. Before lifting the aluminium formwork, it is necessary to check whether the hoisting ropes, fixtures and the lifting rings on each aluminium formwork are in good condition. The aluminium formwork can be transported as a whole by a trailer, or it can be disassembled and transported horizontally by a trailer. When stacking the formwork support, it should be aligned up and down.