Building shuttering for concrete is a model that ensures the shape, dimensions, and relative position of concrete structures. The general structure of building shuttering for concrete includes panels, support systems, connection systems, and anchors. Building shuttering for concrete engineering is a systematic job that includes the design, manufacturing, installation, maintenance, dismantling, and repair of the formwork.

In concrete construction, the time required for the installation, removal, lifting, or slipping of the formwork is generally longer, so the construction of concrete formwork often becomes one of the critical processes in controlling the project timeline.

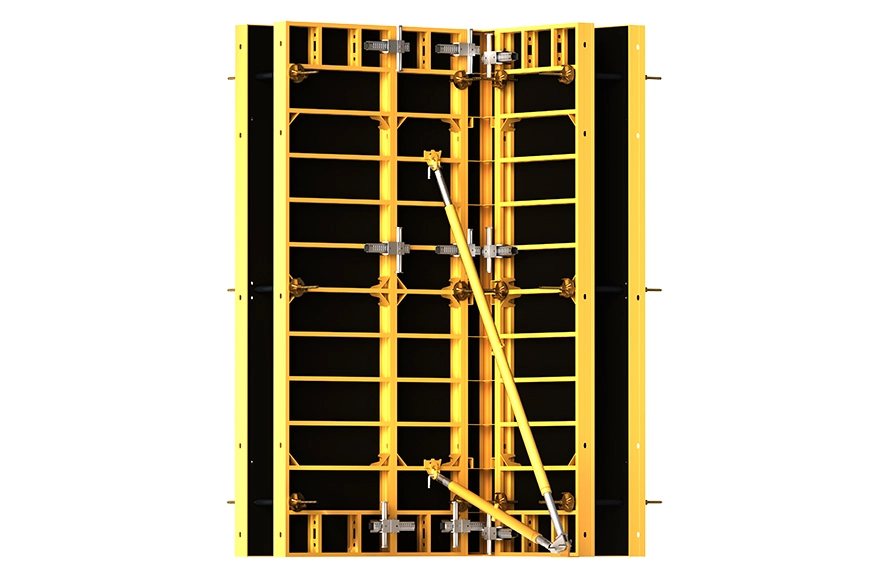

For structurally simple large volume concrete projects (such as gravity dams and arch dams), large combination steel formwork becomes the mainstream choice. This type of building shuttering for concrete is not only strong and durable but also allows for quick assembly and disassembly, improving overall efficiency. Especially with the use of cantilever steel formwork, such as multi-card formwork, construction needs are better met. In roller-compacted concrete dam projects, flip cantilever formwork is widely used due to its flexibility and high reuse rate.

For building parts where high smoothness and precision of the surface are required (such as gate piers, thin arch dams, spillway dam surfaces, etc.), sliding formwork is the best choice. This type of building shuttering for concrete ensures a flat concrete surface while significantly speeding up construction.

In the engineering of facing rock-fill dams, construction of the building shuttering for concrete typically uses trackless sliding mold technology, and the water-facing protective structure is more suitable for using flip formwork to ensure both structural stability and aesthetics.

With the development of underground engineering, the application of steel formwork trolleys in tunnel linings is increasing. Especially in the concrete tile construction after TBM excavation of water supply channel slopes and long tunnels, the efficiency and precision advantages of steel formwork trolleys are fully demonstrated. This technology not only optimizes the construction process but also significantly reduces the wear rate of building shuttering for concrete.

Through scientific formwork selection, the role of building shuttering for concrete in modern engineering is becoming increasingly prominent. From saving resources to improving construction efficiency to achieving green building goals, the development of formwork technology is bringing about a new transformation in the construction industry. Whether it is large-scale infrastructure projects or fine architectural projects, rational selection and optimization of building shuttering for concrete schemes are key to enhancing the competitiveness of projects.