Circular column formworks are a new type of formworks material in the field of construction engineering. These formworks are standardized formworks made according to a certain modulus. By utilizing the flexibility of plywood and molding it with different radii through high-temperature and high-pressure molding, different diameters can be achieved for molding curved surfaces of buildings to complete pouring concrete. How can we improve the utilization rate of circular column formwork and reduce losses?

Purchase circular column formwork with a better cost-performance ratio as much as possible. Lower quality formworks can be soaked in water for a few times to use. Choose materials that are less likely to get waterlogged and have better quality. Although the initial investment may be higher, it is more worthwhile to use them and properly store them after use.

Material management is also crucial. There should be no waste on the construction site. Unused materials should be timely collected and returned, properly stored and distributed in an orderly manner. This is also a method to increase the number of times materials are reused.

Skilled woodworkers can reasonably combine circular column formwork. Larger formworks can be used for floors, smaller formworks can be used for columns and beams, and leftover materials can be used for stairwells. This is the principle of making the most of everything.

Find a skilled and experienced foreman to lead the team. Set a target for the loss rate, reward them for reasonable control of losses, and have them take responsibility for excessive losses. Let them supervise the workers' use of formworks, and they will try their best to use them reasonably.

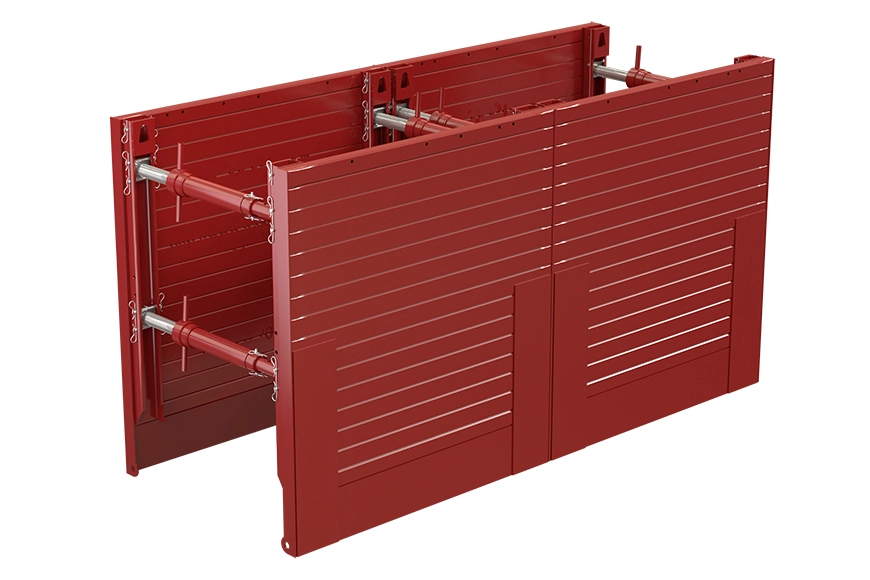

Circular column formworks, including aluminium column formwork, are used mainly for cylindrical structures, mostly in bridge formworks. In modern construction, most structures require the use of circular column formwork. The use of circular column formwork is more effective than traditional square formworks. Usually, circular column formwork are dense and don’t need many steps; they can be used directly, saving some construction time which is necessary for most structures. Here are the construction safety precautions for circular column formwork:

Personnel entering the construction site must wear a safety helmet. For high-altitude operations, safety belts must be securely fastened.

During disassembly, workers should cooperate with each other, work together, and not throw tools when passing them to each other.

formworks supports should be set up neatly, and materials should be placed in order after work is completed.

Lifting and transferring of the formworks should be directed by a designated person and must not be done in violation of regulations.

Before entering the site, the staff must receive environmental protection education to improve their environmental awareness.

Strengthen machinery management and reduce construction noise.

With the professional knowledge of TECON's research and development team from our formwork company, we will provide you with assistance on-site when necessary, and know that our solutions are always cost-effective. You can rest assured that from the first contact to the completion of construction, we are always there to support you. Welcome to inquire.