Reusable plastic formwork is a composite material building formwork that has the advantages of being cold and heat resistant, corrosion and moisture-proof, lightweight, and high strength. It uses polypropylene as the base material, incorporates fiberglass, and is formed using a high-temperature molding process. After strict quality testing, it meets the national first-class standards. Reusable plastic formwork is lightweight, easy to construct, allows for quick formwork removal, and reduces construction costs; it is waterproof, corrosion-resistant, and has stable performance; with normal use, it can be reused for more than 200 cycles.

Save on Labor

The use of reusable plastic formwork in engineering construction changes the labor structure and simplifies the construction process. It requires no large amount of labor; one person can assemble at least 100 meters a day, saving labor and reducing expenses.

Save on Auxiliary Materials

The reinforcement support system is universal and does not require secondary plastering.

High Turnover Rate

Reusable plastic formwork adopts modularized, high-pressure shaping product design and production. The plastic formwork has high strength and good toughness, with a turnover rate of at least 200 cycles.

Recyclable

Since the raw materials of reusable plastic formwork are recyclable, the type of formwork systems for sale is also recyclable. Old and waste molds can all be recycled.

Lightweight and Easy Construction

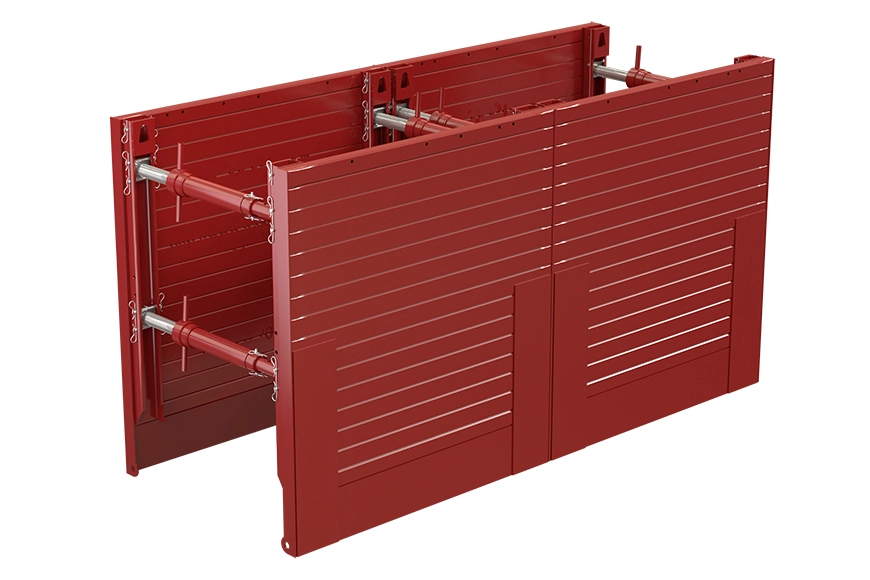

Reusable plastic formwork adopts a ribbed design, reducing the weight of the formwork and making it easy to handle. Through the reasonable distribution of the ribs on the formwork, it enhances various product performances, saves on reinforcement materials, and improves construction efficiency. The formwork uses a buckle-type assembly, requiring no professional carpenters; ordinary workers can easily assemble the formwork, which is convenient and efficient, thus improving construction efficiency.

No Need for Release Agents

Reusable plastic formwork adopts a new process, formed under high temperature and pressure. The surface of the formwork is smooth and flat, does not absorb water, and is wear-resistant. The thermal expansion coefficient of the plastic formwork is vastly different from that of concrete. After the concrete is poured and cured, the formwork automatically separates from the set concrete as the temperature changes, making formwork removal easy.

Choosing TECON's reusable plastic formwork is mainly due to its high strength, penetration resistance, and ease of reuse, which can meet the needs of concrete molds and other construction requirements, thereby improving construction efficiency and reducing costs. Additionally, as one of the top formwork companies in the world, TECON provides better product quality and after-sales service.