Bridge formwork plays a crucial role in construction, providing the necessary support and shape for concrete during pouring and curing. However, ensuring safety during its use is paramount. This blog outlines detailed safety measures and precautions for assembling, disassembling, and working with bridge formwork, helping you maintain a secure working environment.

1. Wear a safety helmet before you installing the bridge deck formwork, check whether the tools used are firm. Tools such as wrenches must be hung on the body with ropes and chains to prevent falling and hurting people. When working, you should concentrate your mind to avoid nails sticking your feet and slipping in the air.

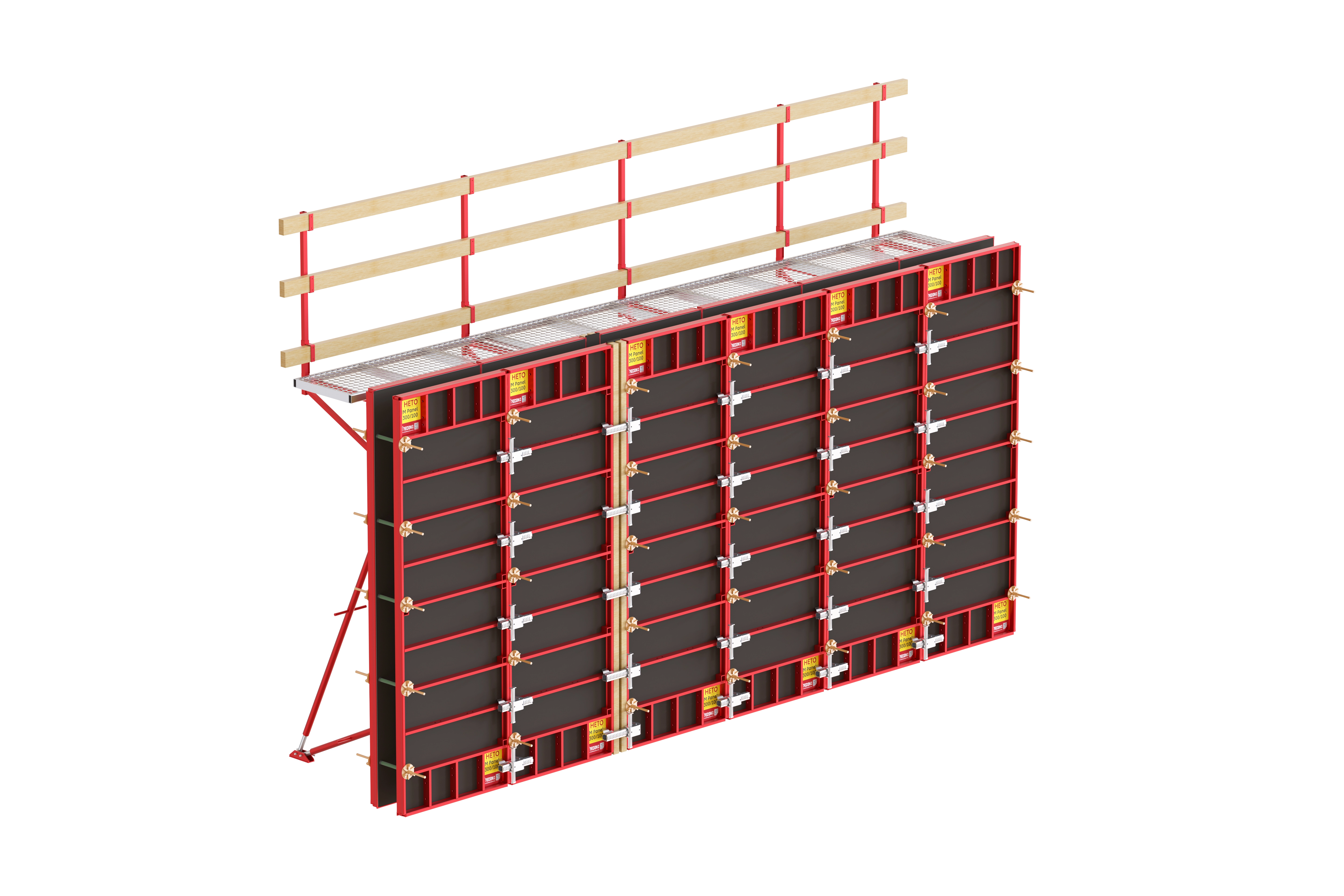

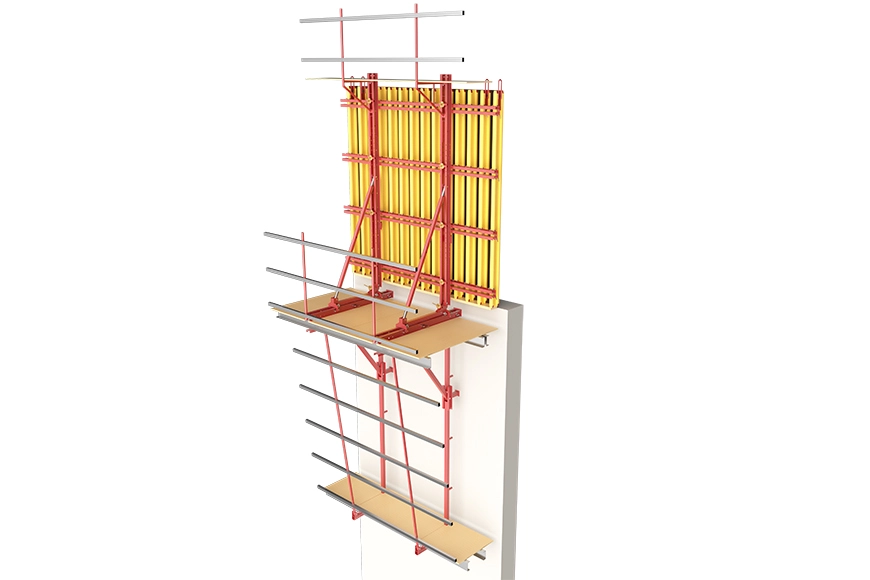

2. When workers are installing and disassembling the bridge formwork above 5 meters, scaffolding and protective railings should be set up. It is forbidden to operate up and down on the same vertical plane, and seat belts should be fastened when working at heights.

3. A large number of bridge formwork and other materials shall not be stacked on the scaffolding.

4. The wires erected on the bridge formwork and the electric tools used should use 36v low-voltage power supply or take other effective safety measures.

5. When you are working at heights, various accessories should be placed in the toolbox or tool bag, and are strictly prohibited from being placed on the bridge formwork & scaffolding; various tools should be hung on the operator or placed in the tool bag, and must not fall.

6. Workers working at height are strictly prohibited from climbing the composite bridge formwork or scaffolding, nor walking on the top of the wall and its bridge formwork.

7. The reserved holes of the bridge formwork should be covered or set up with guardrails. Safety nets should be set at the entrance of the holes.

1. The worker who is responsible for the assembly and disassembly of bridge formwork should be assisted by co-workers at high and low place, and leads the work. The movable parts should be fixed firmly, and it is strictly forbidden to stack them on the scaffolding and throw them.

2. When you are assembling and disassembling bridge formwork, stable climbing tools must be used. When the height exceeds 3.5 meters, scaffolding must be erected. When assembling and disassembling, no one should stand below except the operator. When working at heights, operators should wear seat belts.

3. The sequence and method of the disassembly of the bridge formwork should be carried out in accordance with the provisions of the design in the layout plan, following the principle of supporting first and then disassembling, first non-load-bearing parts, then load-bearing parts and first top and then down. It is strictly forbidden to use a sledgehammer to smash and pry hard when removing the formwork. Click to learn more about dismantling scaffolding procedures.

4. Remove the side bridge formwork first, and then remove the load-bearing formwork.

5. The composite bridge formwork should be dismantled as a whole.

6. The supports and connectors should be gradually dismantled, and the bridge formwork should be dismantled and transferred one by one. The bridge formwork and concrete should not be damaged during disassembly.

7. The removed bridge formwork and accessories should be neatly stacked, and the accessories should be placed in the toolbox for maintenance and storage.

8. It is necessary to remove the mortar in time on the dismantled bridge formwork. If it is difficult to remove, the bridge formwork descaling agent can be used to remove it, and no knocking is allowed.

As one of the leading experts in engineered formwork systems, our wide range of off-the-shelf and custom products ensures that we can provide a solution for your construction project, no matter its size or location. With years of experience in the industry, we founded TECON in 2013, headquartered in Suzhou, China.

With the expertise of our R&D team, our technical team members are there to assist you on-site when necessary, ensuring that our solutions are always cost-effective. If you have any needs, welcome to consult.