Building formworks are a type of framework structure used for protecting support structures so that these formworks can be better utilized. Steel structure building formworks are commonly used in construction, as they can firmly fix building decoration materials such as concrete, making our homes stronger. Today, we will professionally introduce the classification and main uses of building formworks.

Classified by material

Building formworks are classified into different types of formwork in building construction based on the materials used, such as wood, steel-wood, steel, steel-bamboo, plywood, plastic, fiberglass, and aluminum alloy formworks.

Wood building formworks can use various tree species according to local conditions, but generally, they are made of pine and fir. Due to the large amount of wood consumed and low reuse rate of wooden formworks, they should be used as little as possible, or not at all in reinforced concrete structures. Steel-wood formworks are fixed formworks made of angle steel as the frame and wood as the panel. Their advantage is that they can fully utilize short timber and can be used multiple times.

Plywood building formworks are fixed formworks made of plywood as the panel, and angle steel as the frame. Plywood overcomes the shortcomings of wood's uneven directional properties, with excellent strength characteristics. This formwork has the advantages of high strength, low self-weight, no warping or cracking, large panel width, and fewer seams. Steel-bamboo formworks are fixed plates made of bamboo plywood panels and angle steel frames. This formwork has high stiffness, is not easily deformed, is lightweight, and easy to operate.

Steel building formworks are generally made into fixed formworks and assembled into various shapes and sizes using connecting elements. They are widely used in the construction of cast-in-place reinforced concrete structures. Steel formworks involve a large initial investment, but they have a high turnover rate. Therefore, in the process of use, they should be correctly stored and maintained to prevent rusting and prolong their service life.

Plastic, fiberglass, and aluminum alloy formworks have the characteristics of light weight, high stiffness, easy assembly, and high turnover rate. However, due to their higher cost, they are not widely used in construction.

Classified by structure type

Various cast-in-place reinforced concrete structures have different shapes, sizes, and structures. Therefore, the construction of formworks and assembly methods are also different, forming their respective characteristics.

Building formworks are classified by structure type, including basic formworks, column formworks, beam formworks, floor formworks, stair formworks, wall formworks, shell formworks, chimney formworks, and others.

Classified by construction method

On-site assembly type formworks: formworks assembled on-site according to the design requirements of structure shape, size, and spatial position. After the concrete reaches the required strength, the formworks are removed. On-site assembly formworks are mostly fixed formworks and tool-supported formworks.

Fixed building formworks: formworks used for making prefabricated components. formworks are made on-site or in a precast factory according to the shape and size of the components. Various matrix formworks (soil matrix formworks, brick matrix formworks, concrete matrix formworks) belong to fixed formworks.

Mobile building formworks: formworks that can move vertically or horizontally with the pouring of concrete are called mobile formworks.

Building formworks guarantee the quality and safety of concrete engineering, accelerate construction progress, and reduce construction costs.

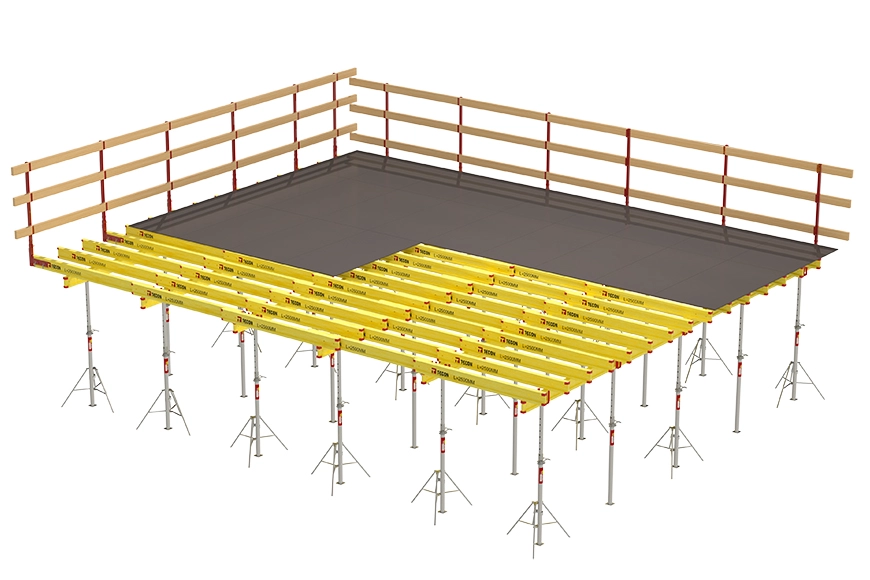

The structure of building formworks used in cast-in-place reinforced concrete structure construction primarily comprises three parts: the panel, supporting structure, and connector. The panel is a load-bearing plate in direct contact with newly poured concrete; the support structure is a temporary structure that supports the panel, concrete, and construction loads, ensuring that the building formwork structure is firmly combined, without deformation or damage; the connector is the accessory that connects the panel with the supporting structure to form a whole.

Building formworks are mold shells and supports for pouring concrete. They can be classified according to material properties, such as building formworks, building plywood, film-coated formworks, multi-layer board formworks, double-sided glued formworks, double-sided film-coated building formworks and more. Building formworks can be classified by construction technology conditions, such as cast-in-place concrete formworks, pre-assembled formworks, large formworks, and jumping formworks.

Combination steel building formworks are a new type of formwork in modern formwork technology, characterized by their versatility, easy installation and removal, and high turnover rate. Using this formwork for cast-in-place reinforced concrete construction, it can be prefabricated according to design requirements into large formworks of beams, columns, walls, and floor slabs, which can be lifted into place as a whole or disassembled individually.

With the professional knowledge of TECON's research and development team from our formwork company, we will provide you with assistance on-site when necessary, and know that our solutions are always cost-effective. You can rest assured that from the first contact to the completion of construction, we are always there to support you. Welcome to inquire.