Maintaining the steel formwork can effectively prolong the service life of the steel formwork and can be used many times. Now let's talk about the method of protecting the steel formwork.

1. Most of the steel formwork in construction projects are stacked in the open air, and it is a big problem to protect the steel formwork from rusting. The steel formwork paint has excellent anti-corrosion and rust resistance. Due to the isolation effect of the paint film, the building steel formwork can be protected from the abrasion of concrete sand and gravel and the corrosion of cement hydrate, thereby prolonging the service life of the steel formwork.

2. The surface of the steel template paint film is bright and full, with good finish, and can naturally form enamel to make up for the surface defects of the building steel template.

3. The thermal decomposition temperature of the paint film of the steel template paint is about 350 °C, and it has good heat-resistant alkali (the physical and chemical properties of saturated calcium hydroxide are not reduced after soaking at 80 °C for 48 hours), which is very suitable for the use environment of building steel templates.

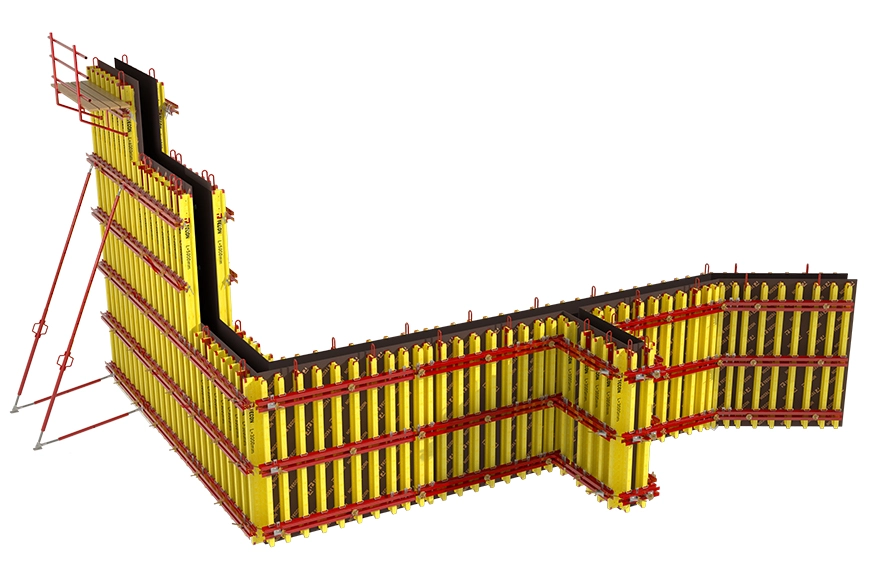

1. The plate has high production precision, tight joints, high rigidity, and it is not easy to deform the square column formwork. The formed concrete structure is accurate in size, dense and smooth.

2. The combined rigidity is large, the bridge formwork is arranged at the staggered joints of the plates, and the assembled panels have the overall rigidity of the plane; the panels are combined into a column-beam formwork, which itself is a load-bearing member, which can improve the overall rigidity, facilitate the overall hoisting, and also make the support structure simplify.

3. The steel shuttering has a long service life, high component strength, good durability, and can be quickly turned around. If the building formwork is repaired in time. With proper maintenance, it can become a long-lasting tool.

4. Steel formwork has a wide range of applications and is suitable for flat formwork, assembly, overall hoisting, sliding form, climbing formwork, etc. of different project scales, structural forms and construction processes.

With the expertise of the TECON R&D team, our technical team members are there to assist you when necessary, and knowing that our solutions are always cost-effective, you can be confident that from the first contact to the completion of construction, we will always be there to support you.

As one of the leading experts in formwork and scaffolding engineering, our wide range of off-the-shelf and custom products ensures that we can provide a solution for your construction project, no matter its size or location.

We encourage everyone on the team to give their best for themselves, colleagues and each client. As a company, we provide the best for our employees, colleagues, partners and customers. Welcome to consult.