When using building formwork, it is the main purpose to ensure the high-quality pouring of concrete. The joints of the building formwork should be guaranteed not to leak, otherwise it will cause the honeycomb surface of the concrete appearance, which will directly affect the quality of concrete pouring. Leave a gap for expansion.

After the building formwork is installed, water it to be moist, but there should be no water accumulation in the building shuttering. There should also be no residue inside the building formwork, which will cause defects such as slag inclusions in the concrete and affect the pouring quality.

The building formwork should be painted with release agent, and the choice of release agent should be appropriate, and the standard should not affect other construction requirements of the project. Moreover, when the release agent is painted, it should avoid contaminating the steel bars, otherwise it will affect the bonding between steel bars and concrete. Or lead to corrosion of steel bars.

When carrying out multi-stage pouring, the bearing capacity of the ground of the lower support should be ensured. If a support is installed, it should be ensured that the upper and lower support columns are aligned, and the backing plate should be prevented under the support. If there are reserved holes, the reserved building formwork should be fixed on the building formwork before pouring. Ensure the size and location of the reserved holes, etc.

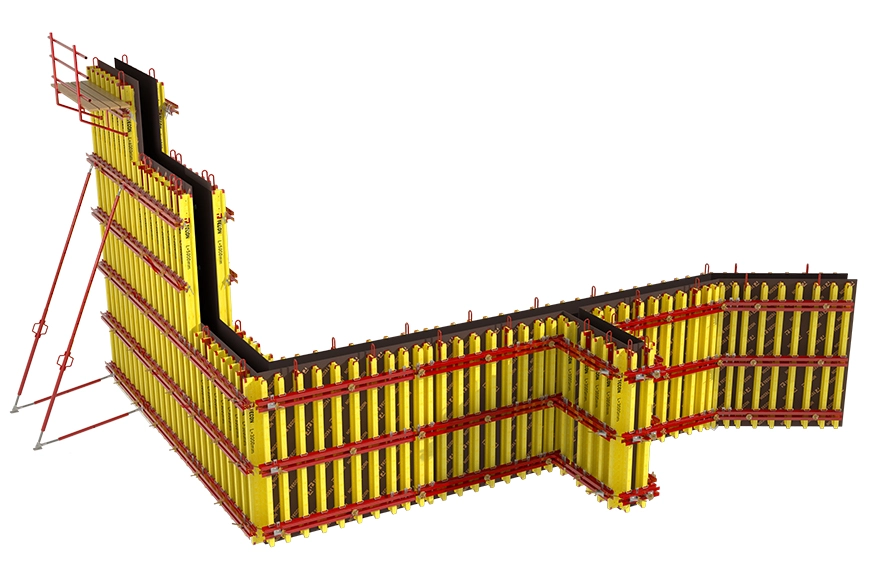

The building formwork is a temporary support structure, which is made according to the design requirements, so that the concrete structure and components can be formed according to the specified position and geometric size, maintain the correct position of the support, and bear its own weight and external force acting on it. And this template will be affected by various factors and produce deformation phenomenon. So, how should we deal with this problem?

1. In the design of building formwork and support system, the self-weight, construction load, the degree of concrete self-satisfaction and the lateral pressure generated during the concrete pouring process should be fully considered to ensure that the formwork and support have sufficient bearing capacity, stiffness and stability. And pay attention to the support spacing at the bottom of the beam, which should be able to ensure that no deformation occurs under the action of concrete self-weight and construction load. If the support bottom is a soil foundation, it should be carefully reinforced, set up drainage ditch, and lay long dunnage or steel bars to ensure support.

2. During the construction of wooden formwork and hollow plastic building formwork, concrete should be poured in time after acceptance to prevent the wooden formwork from being exposed to the sun and rain for a long time.

3. For cast-in-place reinforced concrete beams and slabs with a span of not less than 4m, the building formwork should be arched according to the design requirements. When there is no specific design requirement, the arching height should be 1/1000 - 3/10 of the span.

In addition, when assembling small steel molds, the connecting parts should be placed according to regulations, and the spacing and specifications of purlins and tension bolts should be in accordance with the design requirements.