For many people, how many times can the column timber formwork be turned around is a question that they don't know how to answer. There are many factors that affect the use times of timber formwork for column, so this question is difficult to answer. So what factors affect the turnover times of column timber formwork? In order to solve this problem, the manufacturer needs to consider the slurry leakage problem during concrete pouring when designing timber formwork for column How should column timber formwork manufacturers solve this problem? We will introduce it to you in detail.

1. Reason of manufacturer: there are many turnover times of high-quality column timber formwork products. The use of core materials, glue, surface coating paper and supporting steel strip all have a certain impact on the turnover times.

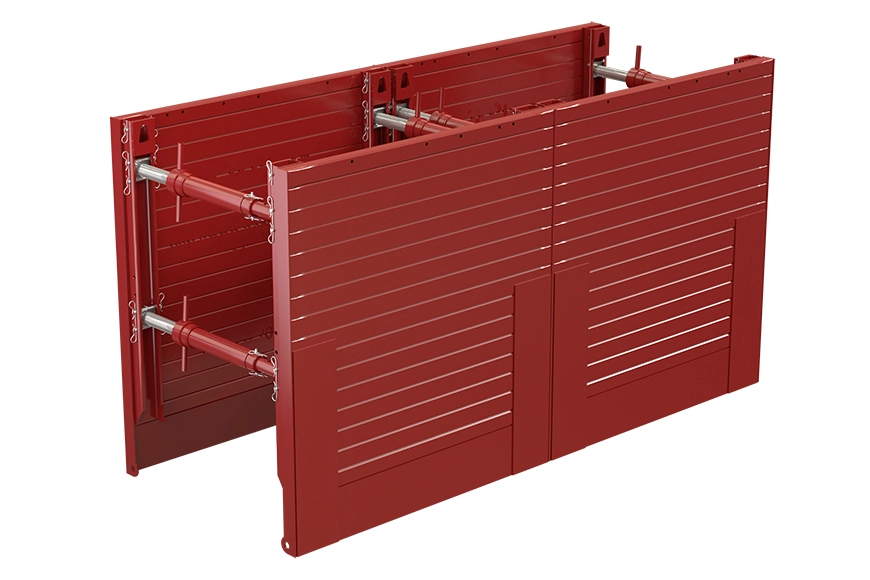

2. Proper preservation: it is best to buckle the two semicircles together, fix them together with two steel bars, and store the timber formwork for column vertically to avoid exposure to the sun and rain to prevent deformation.

3. Usage skills: flexible and reasonable use of column timber formwork can increase the number of repeated use. For example, protecting concave convex groove with adhesive tape and painting can improve the turnover times.

4. Reason for use method: if the carpenter is careful in the use process, the turnover times will be more. It is necessary to avoid knocking, smashing, falling from high altitude and other use methods.

1. Design of widening accessories: when strengthening the wooden cylindrical wooden formwork, the supporting steel belt shall be used for reinforcement. The upper and lower joints shall be reinforced with steel strips to prevent slurry leakage. On the one hand, the requirements for the flatness of the incision of the formwork are high. If the cut is uneven and the gap is too large, it will be easy to leak slurry. The supporting steel belt shall be galvanized to prevent rust.

2. Concave convex groove design: when the column timber formwork is butted, the groove and convex groove are used to avoid slurry leakage. The formwork has high requirements for precision during slotting, and it needs automatic slotting by machine. The notch is too deep to remove the formwork. If the notch is too shallow, it will be easy to leak slurry.

3. Large format design: the height of this shaped formwork can reach 3m, while the height of the same type of formwork, such as steel formwork, ranges from 1m to 2m.

In comparison, the wooden building cylindrical formwork has large width and few nodes. For example, for a column with a height of 5m, there is only one joint with wooden formwork (3 + 2), while the steel formwork has at least 3 joints.

We know that the leakage and formwork shifting of concrete mainly occurs at the joint joints, so the leakage and formwork shifting phenomenon can be greatly avoided by using the advantages of large width and less joints of wooden cylindrical wooden formwork of wooden buildings.

Through the above three methods, the timber formwork for column designed by the concrete formwork suppliers can effectively solve the problems of formwork shifting and leakage of cylindrical formwork in the process of pouring construction to ensure the demoulding and forming effect of concrete cylinder.