1. Classification by structure type

Various cast-in-place reinforced concrete structural components have their own characteristics due to their different shapes, sizes and structures, and the structure and assembly methods of the formwork are also different. According to the type of structure, bridge formwork is divided into foundation wall formwork, pier column formwork, abutment (cap) formwork, beam formwork, crash wall formwork, tunnel formwork, etc.

2. Classification by construction method

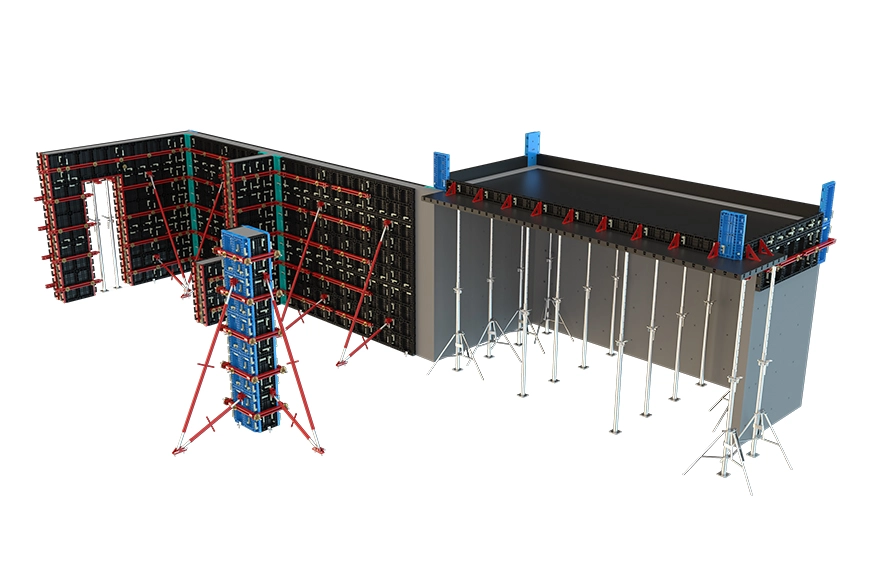

On-site assembly and disassembly formwork: The formwork is assembled on site according to the structural shape, size and space position required by the design at the construction site, and the formwork is removed when the concrete reaches the dismantling strength. On-site assembly and disassembly formwork mostly adopts stereotyped formwork and tool support.

3. Classification by material

According to the different materials used, bridge formwork is divided into wood formwork, steel-wood formwork, plywood formwork, steel-bamboo formwork, steel formwork, plastic formwork, glass fiber reinforced plastic formwork and aluminum alloy formwork, etc.

The bridge shuttering formwork support is used to form the cavity of the concrete member. The bridge formwork support has very strict requirements on its characteristics. For example, it requires that the column of the support should be kept stable and fixed with support rods. Let us introduce the bridge shuttering support below. When checking the rigidity of formwork, support and arch for strength and stiffness requirements, the deformation value shall not exceed the following values:

1. For bridge formwork with exposed structural surface, the deflection is 1/400 of the span of the formwork member;

2. For bridge formwork with hidden structural surface, the deflection is 1/250 of the span of the formwork member;

3. Rods (cover beams, longitudinal beams) that deflect after loading of brackets and arches, their elastic deflection is 1/400 of the corresponding structural span;

4. The panel deformation of the steel formwork is 1.5mm;

5. The deformation of the steel edge and column hoop of the steel formwork is L/500 and B/500 (where L is the calculated span and B is the column width); Load, check and calculate the stress of each section of the vault, arch foot and 1/4 span, stress of iron parts and joints, and check the strength and stability of staged pouring or masonry. In the checking calculation, no matter whether the plate arch or truss arch is considered as the whole section, the overturning stability factor of the checking calculation shall not be less than 1.3.