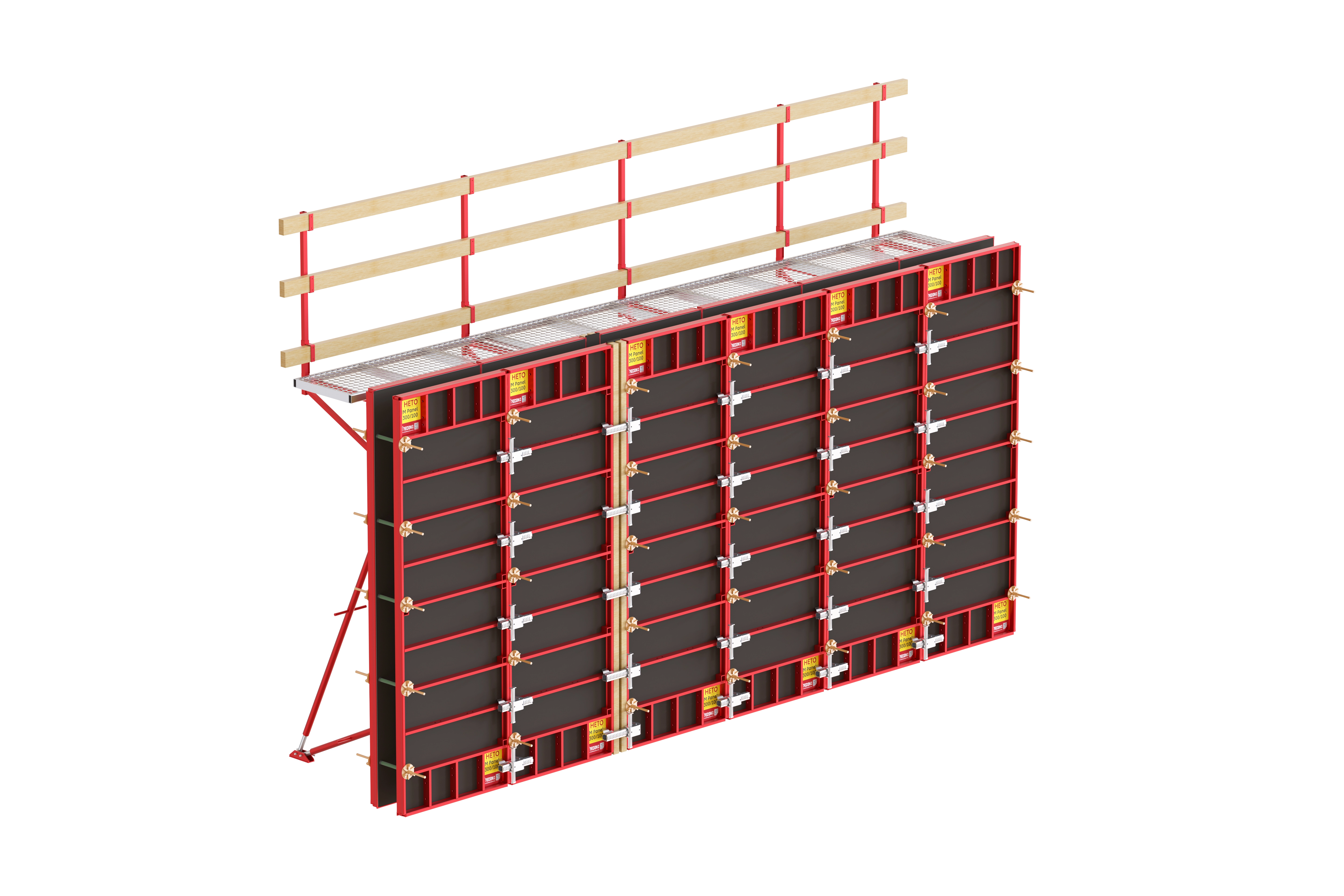

The aluminum alloy formwork adopts independent support, which has a large operating space, personnel passage, material handling and dredging, and is easy to handle on site. Good stability and high bearing capacity. The bearing capacity of Dadu aluminum alloy formwork system can reach 60kn per square meter, which meets the bearing capacity requirements of Dadu residential buildings. Aluminium formwork is suitable for the application of walls, horizontal floors, stairs, windowsills, floating boards, etc., and is still useful for secondary structural forms such as ring beams, structural columns, and anti-sills. Fewer joints, high precision, and good concrete appearance after formwork removal.

The construction period is short. The aluminum alloy formwork system is a quick-release formwork system. A set of formwork can reach one floor in four days under normal construction, and it can better carry out the assembly line construction, which greatly improves the construction progress and saves the processing cost. The service life is long and the cost is low. The normal use turnover of the aluminum alloy formwork can reach more than 150 times, while the price of the aluminum alloy formwork is only 75% of the price of the all-steel formwork, and the amortization fee for each time is more than 30% less than that of the all-steel formwork.

After the aluminium formwork is removed, the surface quality of the concrete is flat and bright, which basically meets the requirements of clear-faced concrete, without the need for plastering, which saves the cost of plastering. There is less construction waste on site, and the support system is concise. All parts of the aluminium formwork system can be reused. After the construction is removed, there is no waste on site. The support system has a simple structure and is easy to dismantle, so the entire construction environment is clean and tidy. Versatility is strong. There are many aluminium formwork standards, and different standard panels can be selected for assembly according to the project; when the used formwork is used to rebuild a new building, only about 20% of the non-standard panels need to be replaced, which can reduce the cost.

All use stereotyped design, factory production and production, and the quality of template engineering is excellent. The construction period of aluminum alloy formwork is short: the aluminum alloy building formwork system is a quick-release formwork system, which is simple and convenient to assemble, and the formwork can be quickly dismantled, which can effectively shorten the construction time and is beneficial to the overall construction progress.

Aluminum alloy formwork has good stability and high bearing capacity: all parts of the aluminum alloy building formwork system are assembled from aluminum alloy plates. After the system is assembled, it forms an overall structure, and its stability is better than that of ordinary wood formwork.

Concrete surface effect after the aluminum alloy formwork is removed from the formwork: After the aluminum alloy building formwork is removed from the formwork, the concrete surface quality is smooth and bright, the concrete forming effect is good, the sensory quality is significantly improved, and the building quality is effectively improved. There is no construction waste on site of aluminum alloy formwork.

The aluminum alloy formwork replaces the traditional formwork, square wood and steel bars, which is equivalent to the formwork + support system.