(1) The support spacing between building formworks is too large, and the rigidity of the steel plate is poor;

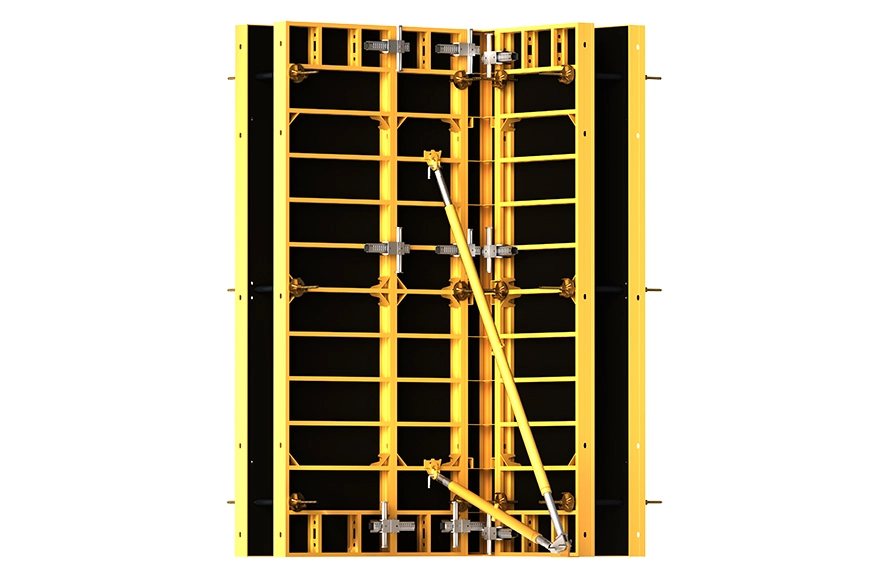

(2) When assembling small steel formwork, it is not set and operated according to regulations, resulting in the poor overall performance of the building;

(3) The speed of pouring wall and column concrete is too fast, the height of one-time pouring is too high, and the vibration is excessive;

(4) The foundation on which the building formwork is placed is not firm, resulting in the formwork not being laid flat and poor waterproof measures. So it caused the foundation to sink;

(5) The construction site adopts a wooden building formwork or plywood construction, and the concrete is not poured in time after passing the experience. Long-term sun and rain cause varying degrees of deformation of the building formwork surface;

(6) The construction personnel did not operate properly when assembling the formwork.

(1) When assembling the small metal formwork, the connecting parts should be placed and operated according to the regulations, and the spacing and specifications of the purlin and the tension bolts should be set according to the design requirements.

(2) When using wooden building formworks and plywood building formworks, the concrete should be poured in time after the acceptance is passed to prevent the wooden building formworks from being deformed by long-term exposure to the sun and rain.

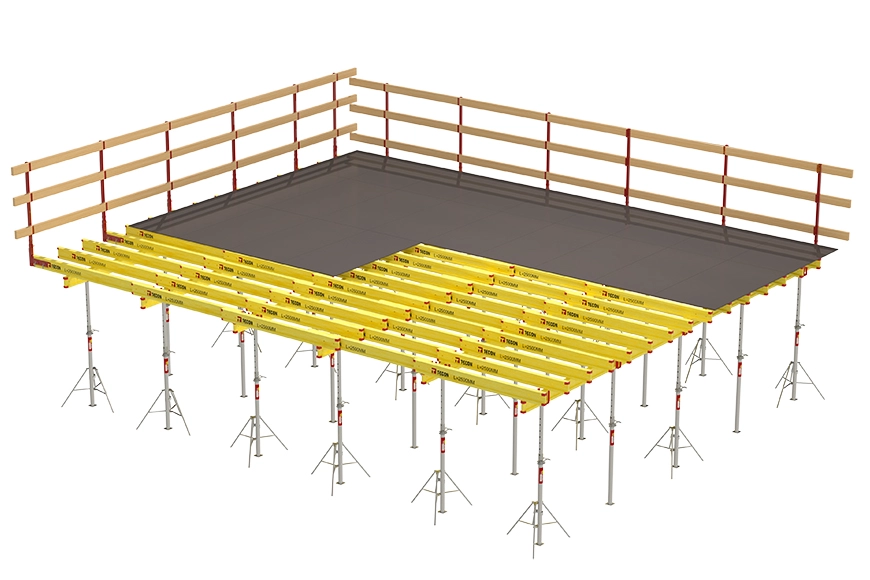

(3) For cast-in-place reinforced concrete slab and beam formwork with a span of not less than 4 meters, the construction formwork should be arched according to the design requirements. When the design has no specific requirements, the arching height should be one-thousandth to five-thousandths of the span.

(4) In the design of building formwork and support system, full consideration should be given to its own weight, construction load, and the self-sufficiency of concrete and the lateral pressure generated during pouring to ensure that the building formwork and support have sufficient bearing capacity, stiffness, and stability.

(5) The spacing between the beam bottom supports should be able to ensure that no deformation occurs under the action of the concrete weight and construction load. If the bottom of the support is a mud foundation, it should be tamped carefully, set up a drainage ditch, and lay long skids or section steel to ensure that the support does not sink.