Circular column formwork is widely used in various fields, so the cleaning and maintenance of circular column shuttering is also essential. What are the steps of maintaining and cleaning circular column formwork? What should we pay attention to during installation? Let's have a look.

1. Thorough cleaning must be carried out to remove all cement fragments from the surface of the circular column formwork. Try to avoid using metal or other sharp tools to remove the cement on the circular column shuttering, so as not to damage the phenolic resin coating of the circular column formwork.

2. After the work, the surface of the circular column shuttering can be coated with film remover. According to the storage conditions and the interval of pouring, the circular column formwork may need to be recoated with film remover before reuse. If it is on the construction site, waste engine oil and waste diesel oil can be used as film remover on the surface of the formwork.

3. The surface coating will age, so it must avoid to being exposed to the sun. In case of wet environment, the steel or plastic packing belt shall be removed. When handling the circular column shuttering with mechanical equipment, attention shall also be paid to re bundling to avoid losses and accidents caused by the falling of the circular column formwork.

When installing and removing the circular column formwork, the crane driver and the installer shall cooperate closely to achieve stable lifting, falling and positioning, so as to prevent large swing and collision with other objects.

Some problems needing attention in installing circular column shuttering:

When considering the support standard load degree of circular column formwork, there is no accurate grasp, which leads to the phenomenon of overweight load; In addition, if the quality of other equipment used is not good, its due function will not be achieved.

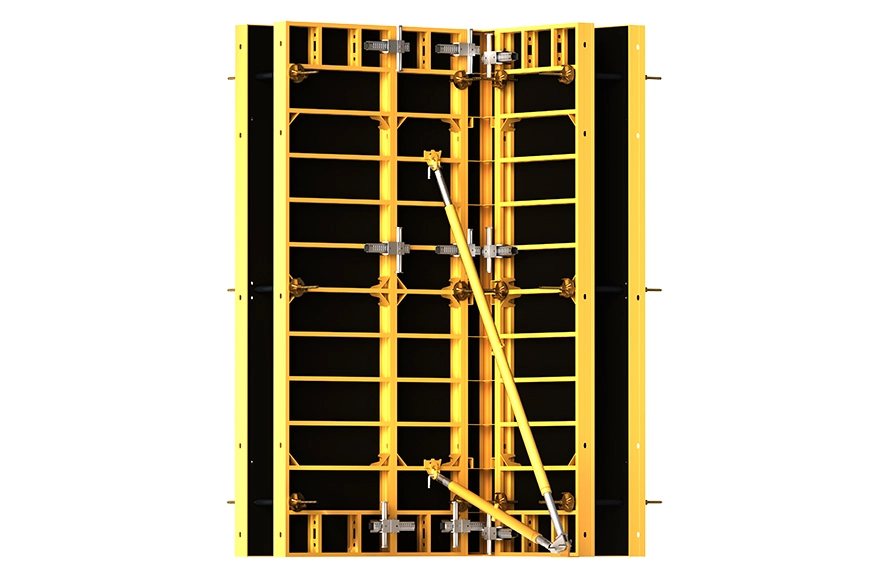

The first is the method of single block in place assembly. First, put the four side formwork of the first section of the column in place, and assemble it with the connecting angle module. The angle formwork should be higher than the flat formwork, then correct and adjust the diagonal, and fix it with the column hoop.

Then, the second section of formwork shall be assembled in the same way based on the corner formwork connector attached to the first section of circular column shuttering to achieve the full height of the cylinder.

During the construction of circular column formwork, the formwork support should be correctly built and firm. We should build it firmly and avoid bad weather for construction.

There is also a single pre assembly method. The single circular template pre assembled in advance is used. After checking that the diagonal line, flatness of plate edge and overall dimension are qualified, it shall be hoisted in place and temporarily supported. Then the second section of circular column shuttering shall be hoisted in place. The U-shaped clamp is combined with the first circular column formwork, and the support is made at the same time.