In the construction industry, the aluminum alloy template is a commonly used product. Let's take a look at the main performance characteristics of the aluminum template:

Design

Before construction, accurate engineering design analysis and detailed construction plans are carried out. The modular, systematic, and standardized product of the template system can solve problems in the design phase during construction.

Overall testing and installation

The aluminum formwork system, which is tested before delivery to the site, ensures that all potential problems are solved in advance. This proactive approach greatly improves the speed and accuracy of actual construction, providing a more efficient and reliable construction process.

High construction efficiency

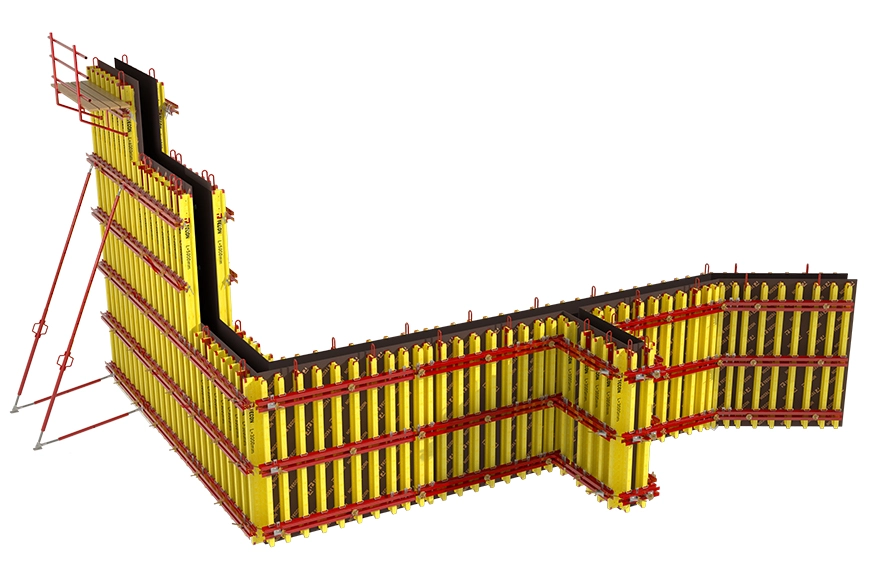

The aluminum template system adopts a pin-and-wedge connection method, and workers can perform operations with simple training. The lightweight aluminum template is usually built layer by layer and does not rely on large lifting equipment, which greatly speeds up the construction progress and improves the construction efficiency.

The aluminum template system uses high-strength aluminum alloy profiles, which are divided into various standard parts, control quantities, and product standards according to different modules for production. The overall accuracy of the template joint is significantly higher than that of traditional templates.

Early dismantling technology: The integrated design of the top mold and support system in the aluminum mold system makes it possible to mix and match standard and non-standard plates. Assembly is quick, and aluminum alloy templates are easier to disassemble and install. The installation is more convenient through pin fixation, which saves material costs.

Aluminum template accessories can highlight their advantages only in standard layers because one set of templates (standard plus non-standard plates) can be used for construction without any changes. In non-standard layers (usually the first or second floor), wooden templates can be used to save costs.

Each assembly of aluminum template accessories is machined in the factory using equipment, ensuring flatness and quality at the joints. Pins are used to connect the holes between each piece. This ensures the appearance and quality of the concrete poured using aluminum alloy templates.

Low average cost of use: Although the purchase unit price per square meter of the aluminum template accessory is higher, its average cost of use is more advantageous compared to other template techniques, especially when it is used in buildings with more than 30 standard layers or repeatedly.

Short construction cycle: The aluminum alloy template technology uses a "fast disassembly system." When the concrete poured on a certain floor reaches a certain strength, the stiffener, template, etc. are removed and moved to the upper floor from the feeding port, and the retaining pole must be stable.

With our professional R&D team and experienced technical team members from our formwork company, we will provide you with help on-site when necessary. Our solutions always have cost-effectiveness, and you can rest assured that we are always there to support you, from the first contact to the completion of the construction. Welcome to inquire.