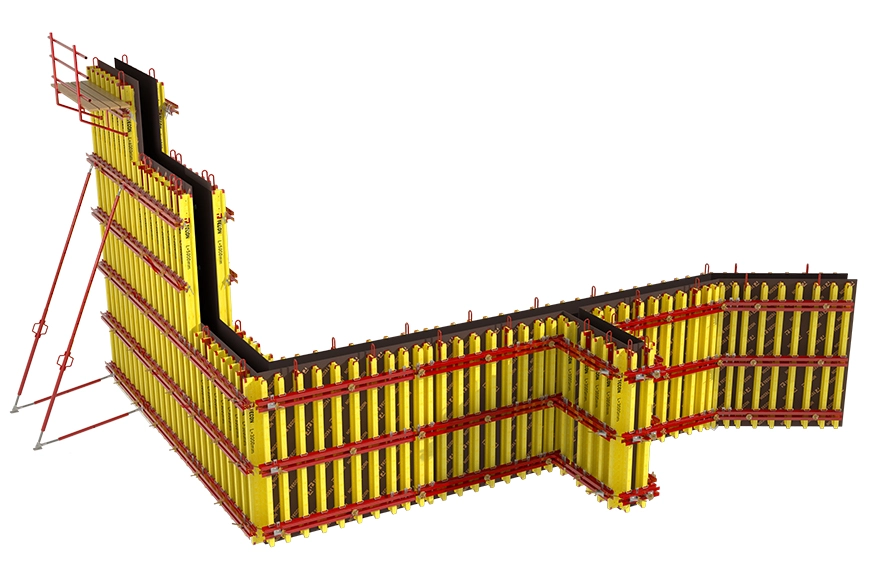

Bridge formworks, as the name implies, are steel formworks used in bridge projects. When installing the supports for these bridge formworks, five regulations must be followed:

Assemble in the order specified in the bridge formwork design to ensure the overall stability of the formwork system.

Accessories must be firmly inserted, and the supporting and diagonal supporting surfaces must be flat and solid, with sufficient compressed area. Pre-buried parts and reserved holes must be accurately positioned and firmly installed.

The bottom surface of the wall and column formwork should be leveled, and the lower end should be close to the pre-set positioning benchmark. There should be reliable support points when installing the steel formwork on the wall and column, and their flatness should be calibrated.

The foundation bridge formwork must be firmly supported to prevent deformation. The bottom of the side formwork diagonal support should be equipped with padding.

After the pre-assembled bridge formworks are lifted into place, the lower end should be leveled and close to the positioning benchmark. Both sides of the formwork should use diagonal supports to adjust and fix their verticality. The horizontal and scissors braces set up for the pillar should be arranged according to the structure and overall stability. For multi-level supporting pillars, the upper and lower floor slabs should have the bearing capacity to bear the load of the upper floor or additional support should be added. The columns of the lower bracket should be equipped with padding plates.

Improper use and handling of bridge formworks may result in formwork deformation. Here are several ways to deal with this situation, see if they are useful for you.

When pouring concrete, it should be symmetrically poured and strictly control the pouring height, especially for door and window openings on both sides of the building bridge formworks. It is necessary to ensure that the concrete is compacted and prevent excessive compaction from causing deformation of various concrete formwork types used in the building.

When designing the building bridge formwork and support system, the first priority is to fully consider the weight of the product itself, construction loads, and the weight of concrete, as well as the lateral pressure generated during pouring to ensure that the supporting capacity and stability of the building bridge formwork are sufficient.

When using wooden building formworks or plywood building formworks for construction, they should be poured with concrete in a timely manner after passing the inspection to prevent deformation due to long-term exposure to sunlight or rain.

For cast-in-place reinforced concrete beams or slabs with spans greater than or equal to 4m, the building bridge formwork should be arched according to the design requirements. When there are no specific requirements in the design, the arch height should be between 1/1000-3/1000 of the span.

As one of the leading experts in the field of formwork and scaffolding engineering, our extensive range of ready-made and custom products ensure that we can provide solutions to your construction projects, no matter how big or small or where they are located. Feel free to inquire.