The pier formwork is one of the main types of bridge formwork, which adopts a perforated tie-rod structure. The shaped steel formwork is composed of panels, vertical and horizontal stiffeners, back corrugations, etc. The strength, stiffness and stability should meet the construction requirements. Let us introduce the installation of the pier body formwork of the bridge formwork.

1. The pier body formwork should be polished before assembling, so that the joints are smooth, and the inner surface of the formwork is free of rust.

2. Connect the formwork in layers on the ground, and use steel plate glue to bond and polish the joints. The template is a shaped steel mold.

Before the template is installed, the structural size, strength, rigidity and surface flatness should be inspected. Then accurately release the outline of the structure and level the base accurately, and control the leveling error within 2mm to ensure that the verticality of the template after assembly meets the requirements of the specification.

Apply mold release agent before assembling, and use special mold release agent for mold release agent. Manually cooperate with tower crane to assemble the formwork, and check the verticality and geometric shape of the formwork for each hoisting section of the formwork. After the support of each layer of formwork is completed, each reinforcement bolt is tightened one by one.

3. The bridge pier formwork should be hoisted with a hoisting pole, which should be installed section by section from bottom to top until the top of the pier. Each time a set of formwork is installed, the bolts should be fastened immediately, and the tension-adjusted cable wind rope and the four-corner tie of the formwork top (the inclination angle of the cable wind rope is about 45°) should be installed, and the position, verticality and elevation of the formwork should be adjusted. Re-measure the line, and carefully check the coordinates of the bridge pier and abutment in addition to checking the elevation when setting the line.

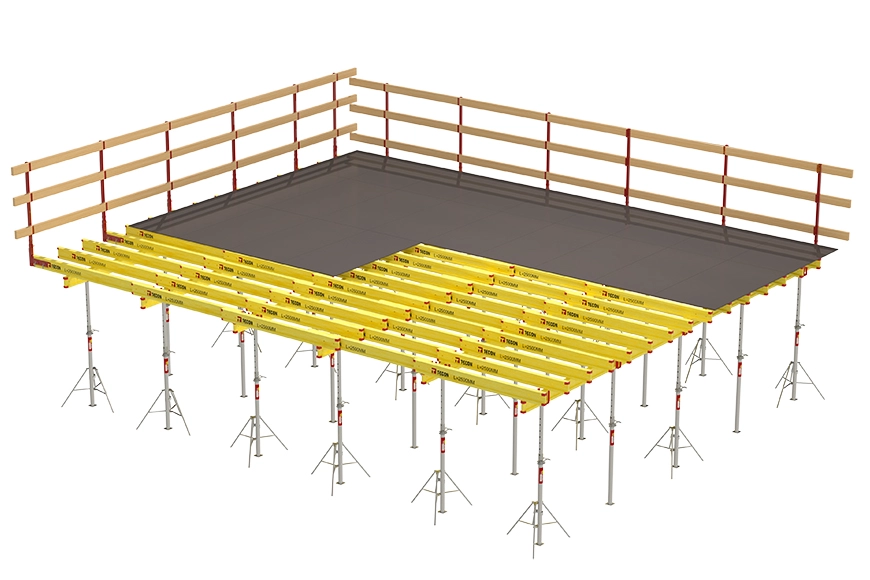

The formwork adopts combined steel formwork and fastener-type steel pipe scaffolding. The formwork is accurately erected and firmly supported, and no formwork and deformation occur when pouring concrete. The working platform shall be set up in a ring with a bowl-type bracket, and shall not be connected with the pier formwork.

For non-load-bearing formwork, the concrete strength should ensure that the surface edges and corners will not be damaged due to the removal of the formwork, or the formwork can be removed only when the concrete strength reaches 1.2Mpa or more. The bottom formwork should be removed when its concrete strength reaches the strength specified in the table below; Before dismantling the bridge formwork, the technician should control the time of dismantling the formwork according to the demoulding test block or according to the concrete mix ratio, temperature, maintenance conditions, etc., and issue a formwork dismantling notice.

The sequence and method of bridge formwork removal and safety measures:

1. The formwork demolition sequence is generally the non-load-bearing formwork first, then the load-bearing formwork, and the side plate first and then the bottom plate. The frame structure formwork removal sequence is generally column → beam side plate → cast-in-place plate → beam bottom plate.

2. When dismantling the bridge formwork, it is strictly forbidden to use a sledgehammer and a crowbar to smash and pry it hard.

3. When removing the formwork, the staff should stand in a safe place. After the formwork of the bridge is completely removed, the formwork, accessories, brackets, etc. should be transported out and stacked.

Note: The dismantled bridge formwork, accessories, etc. are strictly prohibited to be thrown away. They should be stacked according to the designated location, and should be cleaned, repaired and coated in time, and sorted into piles for use.

In the process of demolishing, if any quality problems affecting the structural safety are found, the demolition shall be suspended, and the demolition shall not be continued until it has been dealt with. After the formwork is removed, the board seam tape is cleaned by the carpenter, and there is a little mortar at the seam of the bridge formwork and the bottom of the board, which should be ground with an angle grinder.