Ask everyone a question, do you know what categories of bridge shuttering are divided into? Maybe this problem is a bit stumbling to everyone. Let's share some classification of bridge templates with you.

Various cast-in-place reinforced concrete structural components have their own characteristics due to their different shapes, sizes and structures, and the structure and assembly methods of the formwork are also different. According to the type of structure, it is divided into foundation wall formwork, pier column formwork, bridge abutment (cap) formwork, beam formwork, crash wall formwork, tunnel formwork, etc.

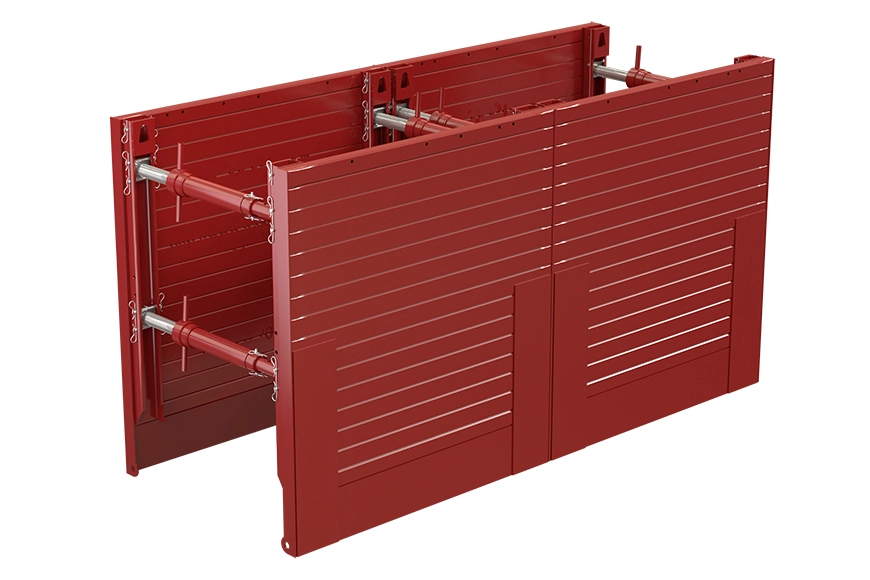

1. On-site assembly and disassembly formwork:

The formwork is assembled on site according to the structural shape, size and spatial position required by the design at the construction site, and the formwork is removed when the concrete reaches the formwork removal strength. On-site assembly and disassembly formwork mostly adopt stereotyped formwork and tool support.

2. Fixed template

Formwork for making prefabricated elements. According to the shape and size of the component, the formwork is made on-site or in the prefabricated factory, the release agent is painted, and the concrete is poured. When the concrete reaches the specified formwork removal strength, the formwork is demolded, the formwork is cleaned, and the release agent is painted, and then the next batch of components is made.

It usually includes various prefabricated beam templates (hollow slab beams, box beams, T-beams, etc.) and other component templates.

3. Mobile template

As the concrete is poured, the formwork can be moved vertically or horizontally, which is called a mobile formwork. Such as the sliding formwork and lifting formwork used for concrete pouring of chimneys, water towers and wall columns;

According to the different materials used, the formwork is divided into wood formwork, steel-wood formwork, plywood formwork, steel-bamboo formwork, steel formwork, plastic formwork, glass fibre reinforced plastic formwork and aluminium alloy formwork, etc.

The material of the wood formwork can be selected according to the actual situation of each region, generally mostly pine and fir. Due to the large amount of wood consumption and low reuse rate of wood formwork, in order to save wood, the use of wood formwork should be minimized or not used in cast-in-place reinforced concrete structures.

The steel-wood formwork is a stereotyped formwork with angle steel as the frame and wooden board as the panel. The advantage is that it can make full use of short wood and can be used multiple times.

The plywood template is a stereotyped template with plywood as the drawing board and angle steel as the frame. The plywood is used as the panel, which overcomes the shortcomings of the anisotropy of wood, and has good mechanical performance. This formwork has the advantages of high strength, low self-weight, no warping, no cracking, large plate width and few seams.

The steel bamboo formwork is a stereotyped formwork with angle steel as the frame and bamboo plywood as the panel. The bridge formwork has high rigidity, is not easily deformed, is light in weight, and is easy to operate.