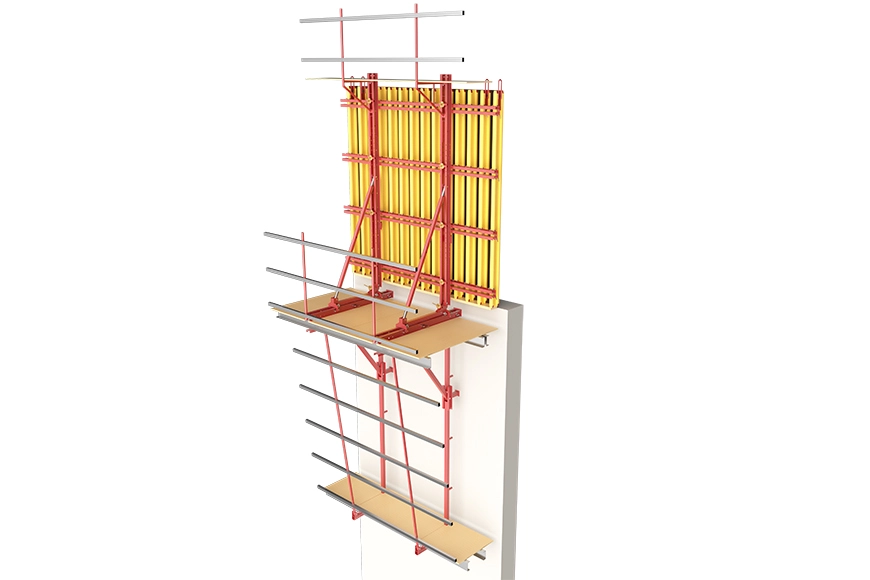

Aluminum formwork system is mainly composed of three parts -- formwork system, accessory system, and support system.

Among them, the aluminum formwork system constitutes the cover needed for the construction of concrete structures, ensuring that there is no slurry leakage during concrete pouring. The accessory system consists of components that connect the formwork to make the entire system a whole. The support system ensures that the concrete structure does not produce deformation during the construction process, and the formwork does not appear bulging or bursting phenomena.

The aluminum formwork is environmentally friendly, saves timber, protects forests, can be reused multiple times, and is easy to install. It also has good surface molding, minimum geometric dimension errors, and minimal debris, making it easy to stack and recycle.

The main system of aluminum alloy formwork, including aluminum beams for sale and other components, is a set, and the bottom support for the floor slab and beam is three sets; the bottom support for the cantilevered structure is six sets. The beam side formwork, wall formwork, and column formwork (non-load-bearing) can be removed one day later; the slab bottom formwork (support not removed) can be removed after 36 hours; the slab bottom support (non-load-bearing) can be removed after 14 days; the beam bottom formwork (support not removed) can be removed after 36 hours; the beam bottom support (non-load-bearing) can be removed after 14 days; and the cantilever bottom support can be removed after 28 days.

Before installing the aluminum formwork, concrete level measurement and horizontal correction work should be carried out at the installation location. During measurement, marking with a positive (+) or negative (-) on the floor is an effective method to indicate measurement results without cumbersome written language. It allows construction workers and operators to judge at a glance which areas need to be corrected. If the concrete surface is more than 8mm higher than the benchmark point, it must be polished to the correct level.

Like concrete level measurement, the measurement of the peripheral guard plate of the flat formwork also needs to be recorded. Then, the floor layout should be provided and verified by a professional layout specialist, and the layout should be continuous and at least 150mm through openings, corners, and other areas. This ensures the correct position of the aluminum formwork before pouring. Based on reference points and layout points, protection and prevention against movement or damage are essential. When transferring reference points from the lower-level, it is required to be accurate by using a transit through floor openings to transfer the layout reference points.