As a scaffolding manufacturer, it is the responsibility to popularize some building knowledge that every worker must master during the construction process. After all, the construction of scaffolding is not only a work frame for formwork, steel and concrete construction, but also a safety protection frame for operators.

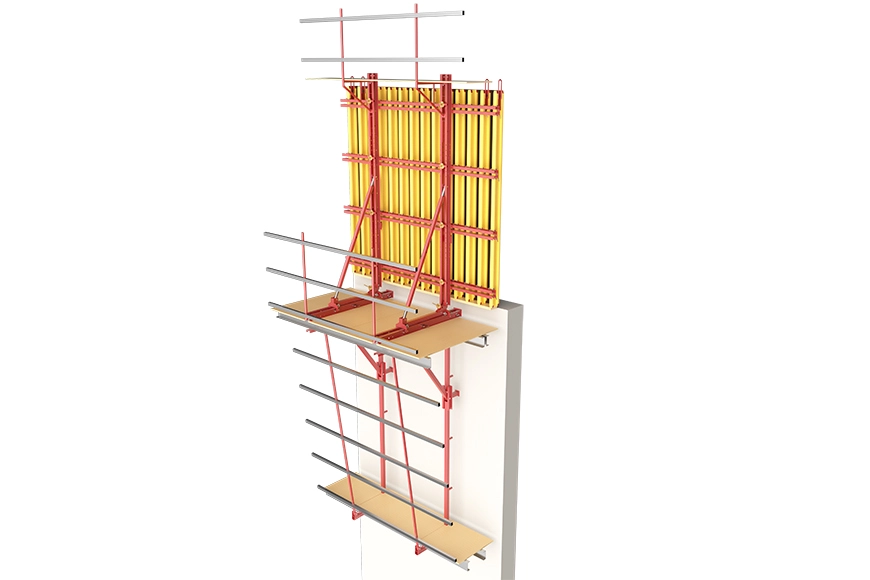

1. Cantilevered outer scaffolding erected with fastener steel pipes. The basic structural measures such as fall protection canopy, scissor braces on the facade, and safety nets should be in place.

2. The steel cantilever beam at the bottom of the scaffolding should be made of I-beam. The spacing is generally controlled within 1.6m. It can not only be fixed on the concrete floor by direct anchor, but also be pulled by steel bar or steel wire rope or steel pipe diagonal bracing.

3. For the cantilever fastener-type steel pipe outer scaffolding, pay attention to the tie setting during the construction process to meet the requirements of the construction plan.

4. Large cantilevered scaffolding and special super-high scaffolding need to be designed for special construction projects. And it can be implemented only after expert argumentation.

5. The fasteners should be made of malleable cast iron, and the material should comply with the current standards. Fasteners must be submitted for inspection and can be used only after passing the inspection. The fasteners used in the scaffolding shall not be damaged when the bolt tightening torque reaches 65N·m.

Scaffolding Accessories:

Pole: The main force-bearing member in the shelf.

Longitudinal horizontal rod: the main force transmission rod.

Transverse horizontal bar: dowel bar.

The cross bracing is a double diagonal brace which is set on the outside of the scaffold and cross into a cross. The angle between the cross bracing and the ground is 45-60 degrees. The length of the scissor brace is lapped, and the lap length is not less than 1m. Two rotating fasteners are used to fix on the protruding end of the Transverse horizontal bar or the vertical rod that intersects it.

The buckling point where the vertical rod, the longitudinal horizontal rod, and transverse horizontal bar (small cross rod) abut against each other is called the main node. The large crossbar (longitudinal horizontal rod) should be tied to the inside of the vertical rod. The distance from the center line of the two fasteners at the main node to the main node should not be greater than 150mm, and the specific spacing is calculated based on calculation.

The vertical and horizontal distance of the vertical pole, the spacing of the longitudinal horizontal bar and the erection of the transverse horizontal bar shall meet the design requirements of the construction scheme. During the use of the scaffolding, it is strictly forbidden to remove the longitudinal and transverse horizontal bars, longitudinal and horizontal bottom sweeping bars and wall connecting pieces at the main node.