Plastic formwork is a composite material extruded at 200 ℃ with advanced products and technology on the basis of digesting and absorbing European advanced equipment manufacturing technology and half height processing experience. Plastic formwork is a kind of energy-saving and green environmental protection product. It is a new product after wood formwork, combined steel formwork, bamboo wood plywood formwork and all steel formwork.

(1) It is smooth and neat. After demoulding, the surface smoothness and finish of the concrete structure exceed the technical requirements of the existing fair faced formwork without secondary plastering, which saves labor and materials.

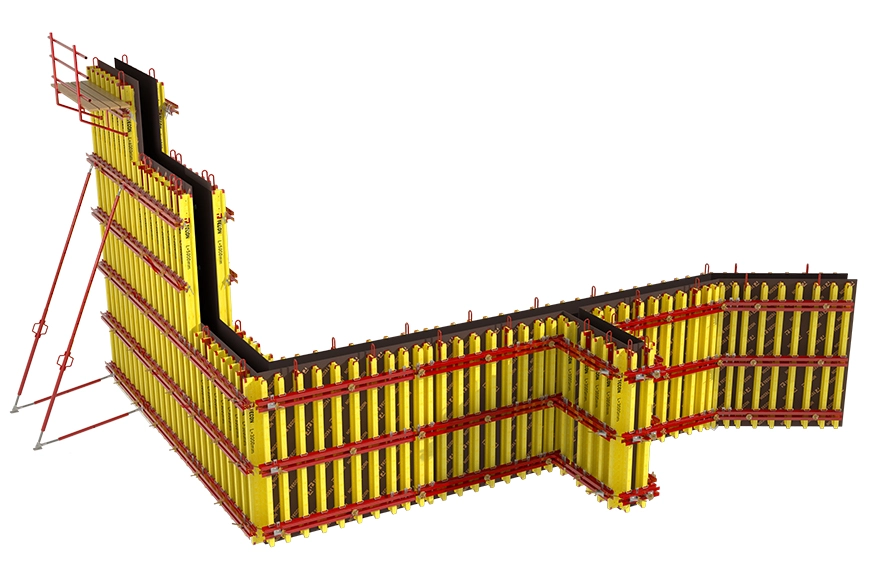

(2) It is light, easy to install and adaptable. It can be sawed, planed, drilled and nailed to form any geometric shape at will to meet the needs of various shapes of building formwork.

(3) It is easy to demould. The concrete does not stick to the surface of the board, no release agent is needed, and it is easy to release and clean ash.

(4) The plastic formwork is stable and weather resistant. It has high mechanical strength, no shrinkage, no wet expansion, no cracking, no deformation, stable size, alkali resistance and anti-corrosion, flame retardant and waterproof, rat and insect repellent at - 20 ℃ to + 60 ℃.

(5) It is conducive to maintenance. The formwork does not absorb water and does not need special maintenance or storage.

(6) The plastic formwork has strong variability. The type, shape and specification can be customized according to the requirements of construction engineering.

(7) It reduces costs. The turnover time is a lot for that of the plane formwork is not less than 30 times and that of the column beam formwork system is not less than 40 times, and the use cost is low.

(8) It is energy saving and environmental friendly. Leftover materials and waste formwork can all be recycled with zero waste discharged.