Improper use and handling of bridge formwork will cause formwork deformation. For this situation, there are a few ways to deal with it, and see if it works for you.

1. When pouring concrete, it is necessary to evenly and symmetrically without cutting, and strictly control the pouring height, especially on both sides of the bridge formwork for the door and window openings, to ensure that the concrete is vibrated and compact, and to prevent the deformation of the building bridge formwork caused by excessive vibration.

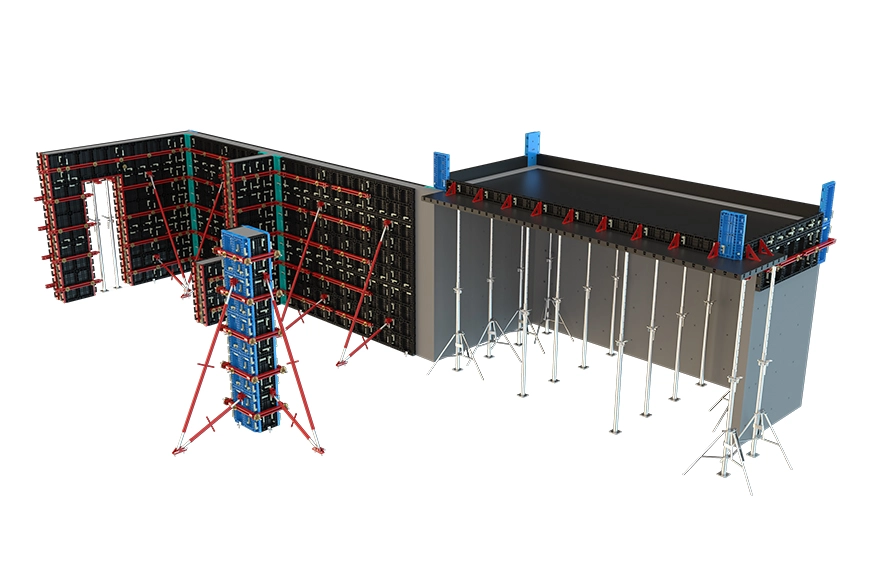

2. When designing the formwork and support system of the building bridge, the first thing to do is to fully consider the self-weight of the product itself, the construction load, the self-weight of the concrete and the lateral pressure generated during pouring and tamping, so as to ensure that the bridge formwork support has sufficient bearing capacity and stability.

3. When using wooden building formwork and building formwork plywood for construction, concrete should be poured in time after passing the inspection to prevent the wooden building bridge formwork from being deformed by long-term exposure to sunlight or rain.

4. For cast-in-place reinforced concrete beams, slabs, and building bridge templates with a span of not less than 4m, the arching should be carried out according to the design requirements; when there are no specific requirements in the design, the height of the arch is preferably 1/1000-3/1000 of the span.

If the bridge formwork is to be officially put into use and play a superior use effect, it is inseparable from the common support of accessories. So, do we have any specific requirements when designing the accessories of bridge formwork? The design requirements for the accessories of the bridge formwork are as follows:

1. The bridge template reinforcement design at the head position

The thickness of the wall in the wall framework is shrinking, so the plug board is configured as a wooden bridge formwork. The steel bridge formwork and the wooden bridge formwork are reinforced with hook bolts at the outside corners. The arrangement spacing of the hook bolts is determined according to the position of the back corrugation of the wooden formwork.

2. Reinforcement design of inner corner position

The steel bridge formwork system adopts two reinforcement methods: fixture and straight back corrugation:

(1) The fixture connection needs to be filled with wood at the joints to ensure a 5mm groove size.

(2) Use 3 reinforced back flutes on each side of the straight back flute to connect the standard height angle die.

3. Calculation of bridge formwork reinforcement system

4. Material determination of bridge formwork reinforcement system

The steel used for the steel bridge formwork is Q235, E=210 000N/mm, σ=215N/mm.

To sum up, we can see that the requirements are very strict no matter in the design of bridge formwork or in the design of bridge formwork accessories.

Only by taking every detail seriously, can the bridge formwork play its due performance in the subsequent use process, and at the same time pay attention to maintenance, in order to prolong the service life and play a long-term work effect.